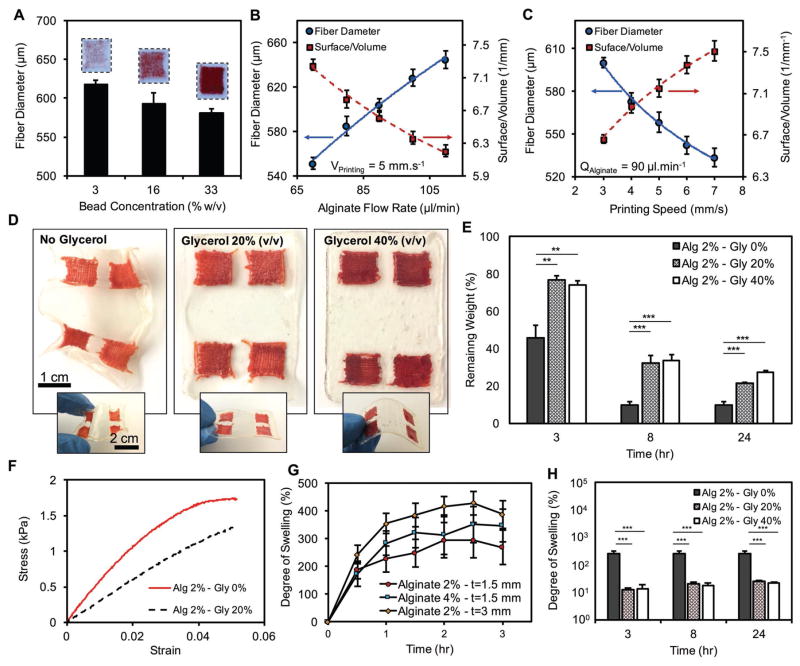

Figure 2.

Characterization of the fabrication process of GelDerm and its physical properties. A) Effect of bead concentration on the diameter of printed fibers. Higher bead densities resulted in darker colors. During the extrusion and 3D printing of the sensors, fiber diameter and surface -to-volume ratio was controlled by adjusting B) alginate flow rate, and C) the travel speed of the nozzle. D) Effect of blending glycerol with alginate on the mechanical integrity and flexibility of the dressings. E) Addition of glycerol to alginate reduced the dehydration rate of the dressing significantly. F) Stress–strain curve for dressing made from pure alginate and alginate–glycerol blend. G) Degree of swelling of the dressings as a function of alginate concentration and thickness. H) Addition of glycerol to alginate reduced the degree of swelling significantly. Error bars represent the SD (n = 3); **p < 0.005 and ***p < 0.0005.