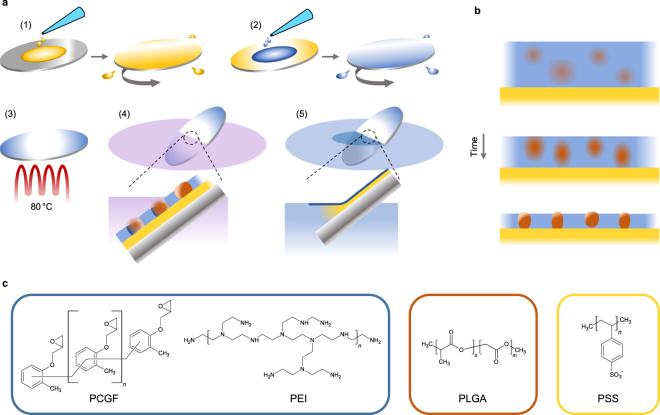

Figure 1.

Fabrication of perforated nanomembranes. (a) Illustration of the fabrication procedure: (1) Sacrificial layer casting onto polished silicon wafer. (2) Coating of the nanomembrane casting solution containing PEI, PCGF and PLGA dissolved in chloroform onto sacrificial layer. (3) Baking step to crosslink thermoset resin component. (4) Selective dissolution of PLGA by immersion into chloroform to create perforations in the continuous nanomembrane matrix. (5) Immersion into water releasing the nanomembrane from the wafer onto the water surface. (b) Schematic of phase separation events occurring during spin coating illustrated at several points in time. (c) Chemical structures of the polymers used for nanomembrane fabrication: Thermoset resin constituents poly[(o-cresyl glycidyl ether)-co-formaldehyde] (PCGF) and branched polyethyleneimine (PEI) comprise the nanomembrane matrix, poly(D,L-lactide-co-glycolide) (PLGA) acts as phase separating porogen and polystyrene sulfonate (PSS) is used as a water soluble sacrificial layer.