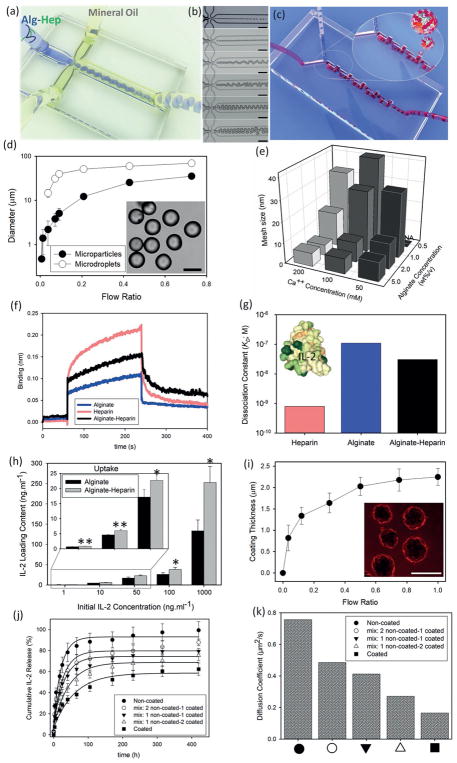

Figure 1.

Microfluidic generation and coating of alginate-heparin (Alg-Hep) microparticles for controlled release of IL-2. a) Schematic representation of a microfluidic droplet generator device, that is applied to form (Alg-Hep) microparticles via sheath hydrophobic flows. b) Diameter of Alg-Hep microparticles (1 wt%/v) is controlled by changing the volumetric flow rate ratio of aqueous to oil phase (○). Equilibrium diameter of microparticles as characterized after gelation process at calcium ion bath (●). Inset: microscopy image of a typical batch of Alg-Hep particles formed at flow ratio of 0.45. c) Microscopic images of Alg-Hep microdroplets formed at different flow ratios resulting in different sizes from 400 nm to 30 μm. d) Schematic illustration of the serpentine micromixer used to coat Alg-Hep particles with chitosan layer. e) Quantification of mesh size analysis of microparticles as a function of calcium ion and Alg-Hep concentrations. f) Biolayer interferometry sensorgrams showing the binding kinetic of IL-2 to alginate, heparin, and Alg-Hep functionalized surfaces. g) Calculated dissociation constants (KD = koff/kon) based on the curve fittings for IL-2 bindings at various concentrations of 5–200 × 10−9M; Inset is the 3D representation of IL-2 (PDB ID: 1M47; colored based on hydrophobicity). h) IL-2 binding efficiency of alginate and Alg-Hep microparticles at various initial concentrations of IL-2 after 12 h of incubation. The presented data are expressed as average ± SD. The results were analyzed using unpaired t-tests. NA: We could not make particles from 0.5% alginate and 50 × 10−3M calcium. i) Microfluidic tuning of coating thickness via changing the flow ratio between Alg-Hep particles and chitosan polymers. Inset: Fluorescence images of RITC-labeled chitosan coated Alg-Hep particles. IL-2 release kinetic of microfluidic-synthesized microparticles prepared from different precursor formulations in PBS at 37 °C j) and calculated diffusion coefficients of studied microparticles (k).