Table 1. Optimization of reaction conditions a .

| |||

| Entry | L | Base | Yield b (%) |

| 1 | dmpe | K3PO4 | 51 |

| 2 | dmpe | KOtBu | 84 |

| 3 | dmpe | NaOtBu | 80 |

| 4 | dmpe | CsOH | 82 |

| 5 | dmpe | KOH | 78 |

| 6 | dmpe | Et3N | 0 |

| 7 | dmpe | K2CO3 | 4 |

| 8 | dmpe | — | 0 |

| 9 | — | KOtBu | 0 |

| 10 c | dmpe | KOtBu | 0 |

| 11 | dppb | KOtBu | 11 |

| 12 | dppp | KOtBu | 15 |

| 13 | dppm | KOtBu | 4 |

| 14 | P(p-Tolyl)3 | KOtBu | 4 |

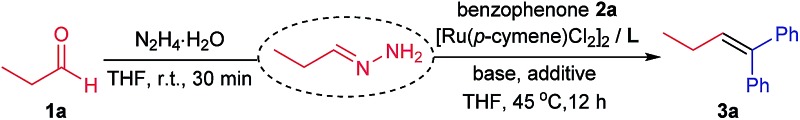

a 1a (0.28 mmol, 1.4 equiv.), N2H4·H2O (0.3 mmol, 1.5 equiv.), THF (0.14 mL), rt, 30 min; 2a (0.20 mmol, 1.0 equiv.), [Ru(p-cymene)Cl2]2 (0.003 mmol, 1.5 mol%), ligand (0.006 mmol, 3.0 mol%), base (0.1 mmol, 50 mol%), additive: CsF (0.15 mmol, 75 mol%), 45 °C, 12 h, under N2.

bYields were determined by crude 1H NMR using mesitylene as an internal standard.

cWithout [Ru(p-cymene)Cl2]2.