Abstract

We have developed a self-blotting TEM grid for use with a novel instrument for vitrifying samples for cryo-electron microscopy (cryoEM). Nanowires are grown on the copper surface of the grid using a simple chemical reaction and the opposite smooth side is used to adhere to a holey sample substrate support, for example carbon or gold. When small volumes of sample are applied to the nanowire grids the wires effectively act as blotting paper to rapidly wick away the liquid, leaving behind a thin film. In this technical note, we present a detailed description of how we make these grids using a variety of substrates fenestrated with either lacey or regularly spaced holes. We explain how we characterize the quality of the grids and we describe their behavior under a variety of conditions.

Keywords: cryoEM vitrification, Spotiton, nanowire grids, TEM grids

We are developing a novel instrument, called Spotiton, (Jain et al., 2012; Razinkov et al., 2016) for vitrifying samples for cryo-electron microscopy (cryoEM). The device uses robotic arms to dispense a controlled volume of sample onto a “self blotting” grid that is subsequently plunged into a cryogen for vitrification. The self-blotting grids typically consist of a sandwich where one side is copper and the other is composed of a different metal, for example rhodium, palladium, or gold (see figure 1). Nanowires are grown on the copper surface of the grid using a simple chemical reaction and the opposite smooth side is used to adhere to a holey sample substrate support, for example carbon or gold. When small volumes of sample are applied to the nanowire grids the wires effectively act as blotting paper to rapidly wick away the liquid, leaving behind a thin film. We previously described some early results using these nanowire grids (Razinkov et al., 2016) showing that they could be used with a lacey holey carbon substrate to vitrify a variety of samples (70S ribosomes, HA, Apoferritin) using Spotiton to apply small volumes (~2.5–16 nL) to a stationary grid that is then rapidly plunged into liquid ethane. In the latest evolution of the device, we apply smaller volumes (~2nL) to a moving grid to deposit a stripe of sample across the diameter of the grid (see reference to companion paper).

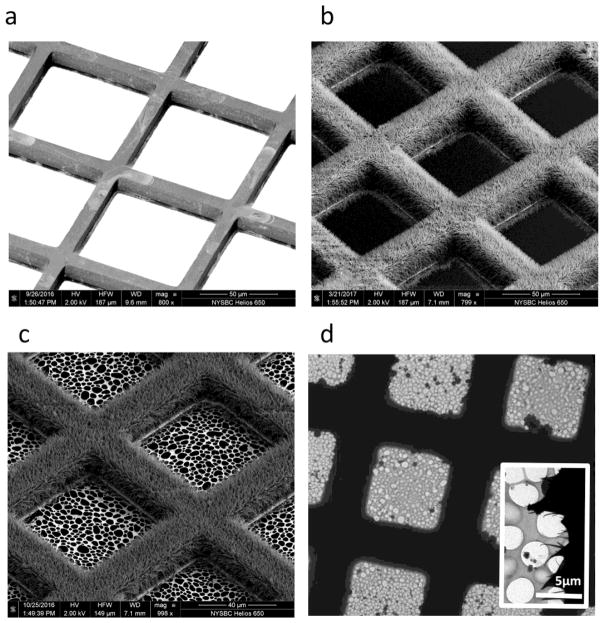

Figure 1.

SEM images of (a) 150 mesh Cu/Rh grid with the copper side facing up, a layer of rhodium underneath; (b) 300 mesh Cu/Rh grid after 3 minutes incubation in nanowire solution (see text); (c) lacey gold film adhered to the rhodium side of the nanowire grid. (d) TEM image of a sample vitrified on a carbon substrate nanowire grid; the nanowire can be seen protruding into the edge of the grid squares.

In this technical note, we present a detailed description of how we make these grids using a variety of substrates fenestrated with either lacey or regularly spaced holes. We explain how we characterize the quality of the grids and we describe their behavior under a variety of conditions. These nanowire grids have now been used to vitrify hundreds of grids from dozens of different samples. They can be manufactured in a robust and reproducible manner and appear to have no deleterious effects on either the sample or the electron microscope. This note is intended as a companion to a paper describing the current version of the Spotiton instrument (paper submitted).

Previously we have used both copper (Cu) and palladium (Pd) and copper and rhodium (Rh) sandwich grids because they are both readily commercially available. We initially used Cu/Pd grids but we found that the Pd layer is quite thick (~5um) and can result in somewhat thicker ice than desired. Thus we have now switched to using Cu/Rh grids; the thin rhodium layer (~1 um) covers one side of the grid bars very effectively to prevent the copper underneath from reacting to the nanowire solution. This ensures a smooth Rh surface which is used to adhere to a plastic lacey, or regularly patterned (Fukami and Adachi 1965; Marr et al., 2014), holey film (see Figure 1). The plastic film is then coated with either carbon or gold and the plastic is subsequently removed to result in a clean carbon or gold substrate. The sample is deposited onto these grids with the nanowire surface facing up so that the sample spreads across the substrate until it comes in contact with the nanowires after which it is rapidly wicked away. A protocol for making the nanowire grids is provided in Box 1 and illustrated in Figure 2. We have found that 300 mesh grids are a good choice as they provide a reasonably large area of substrate, close enough proximity to the nanowires to provide rapid wicking, and are strong enough to withstand the impact force of the Spotiton delivered droplets. We estimate that a 300 mesh nanowire grid can absorb up to ~100nL of liquid into the nanowires. We also note that the nanowire girds backed with gold substrate provide the expected stability of gold grids (Russo and Passmore, 2016) (see supplementary videos V1 and V2). When exposed at a tilt angle of 45° and a dose rate of 20e-/Å2/sec for 2 seconds, the carbon substrates can be seen to move laterally by ~15nm while the extent of the movement for gold is <~1nm.

Box 1. Protocol for making nanowire grids.

Materials and chemicals needed: ddH2O, 10M NaOH, 0.52 M ammonium persulfate solution, 300 mesh Copper/Rhodium Maxtaform Grids (EMS or Ted Pella), lacey plastic film or patterned plastic film, carbon rod (EMS, cat#70210) or 0.20 mm diameter gold wire (EMS, cat#73100).

-

1

Make fresh nano-wire growing solution: 2 parts dd H2O +1 part 0.52M APS +1 part 10M NaOH (500ul dd H2O+250ul 0.52M APS+250ul 10M NaOH), mix it well before use.

-

2

Float a 300 mesh Cu/Rh grid on top of a 25 ul drop of nanowire solution sitting on parafilm, such that the copper side of the grid is facing down into the solution (see figure 2a).

-

3

After 3 minutes, rinse the grid 2x in sequential drops of dd H2O.

-

4

Place the grid onto filter paper to dry.

-

5

Examine the grid under a light microscope at 500X magnification. Nanowires should be clearly observable on the copper surface (see figure 2b). The density of the nanowires will be related to the incubation time of the grid in the nanowire solution and this time can be adjusted to achieve the desired nanowire density.

-

6

Float holey plastic film (either lacey (Fukami and Adachi, 1965) or patterned (Marr et al., 2014)) onto a clean water surface in a glass container (about 12 cm in diameter).

-

7

Place nanowire grids, nanowire side up, onto the film, keeping a ~2 mm gap between grids (see figure 2c)

-

8

Place a piece of parchment paper on top of the film with grids and quickly lift the grids and film out of the water.

-

9

Lay the parchment paper with grids facing up on top of filter paper to dry with weights on the corners to prevent curling of the paper (see figure 2d).

-

10

Coat a layer of ~12 nm carbon film onto the top (nanowire side) of the grids. We used a Leica ACE600 carbon coater for this purpose.

-

11

Quickly dip (~1 second) the coated grids into an Acetone bath to remove the Lacey plastic film.

-

12

Place the grids in an oven at 80°C overnight before use which will help to prevent the carbon film from breaking.

For making nanowire grids with gold film, additional steps are as follows:

-

13

Evaporate a thin layer of gold, ~10 nM, onto the carbon substrate nanowire grids from step 12. The nanowire side should be facing down while coating the gold film. We used an Edwards auto306 evaporator.

-

14

Remove the carbon film using a plasma cleaner with the nanowire side facing up. We used a Gatan Solarus model 950 plasma cleaner at full power for 5 minutes using an argon and oxygen gas mix.

Figure 2.

(a) Nanowire grids floating on droplets of nanowire solution. (b) Nanowire grid observed under the light microscope before (left) and after (right) exposure to the nanowire solution. (c) A raft of holey plastic film floating on a water bath with nanowire grids placed on top. (d) The raft of nanowire grids drying out on filter paper.

The nanowire grids are quite efficient to make; the incubation time in the chemical mix is ~3 minutes and you can place one grid down onto the nanowire solution every 10 seconds once the workflow is optimized. We typically make about ~100 grids per batch and the yield is close to 100%. Each new batch of commercially available Cu/Rh sandwich grids needs to be tested to determine how the grids respond to the nanowire solution prior to making a large batch of nanowire grids. We have found that some batches of grids may not grow nanowires efficiently in the standard 3 minute incubation time and some will not float on top of the nanowire solution. This is likely due to variations in the quality and purity of the materials used during manufacturing and happens rarely enough that we simply discard batches that do not behave well.

Nanowire grids backed with carbon substrate behave quite reproducibly and it is fairly straightforward to estimate conditions on the Spotiton instrument that will result in a satisfactorily even stripe of ice across the grid. This is because there is a good correlation between how long the grid remains at high humidity (~85%RH) inside the Spotiton chamber and the time required to wick the sample away. Typically, the time to wick away the sample stripe varies from ~40 msecs at the beginning of the grid dwell time to ~200 msecs after 30 seconds of dwell time inside the humidity chamber. Nanowire grids backed with gold substrate are less predictable, the wicking speed is very fast, ~30 msecs, at the beginning of the dwell time, but rapidly becomes much slower, typically ~500 msecs, after only 10 secs inside the humidity chamber. However, if a thin layer of carbon (~5 nm) is deposited onto the nanowire grid gold substrate, these grids will again behave like the regular carbon substrate grids. This effect is likely related to the carbon vs. gold coating that is deposited onto the nanowires when the substrates are being made combined with the rather hydrophobic nature of the gold substrate as compared to the carbon substrate.

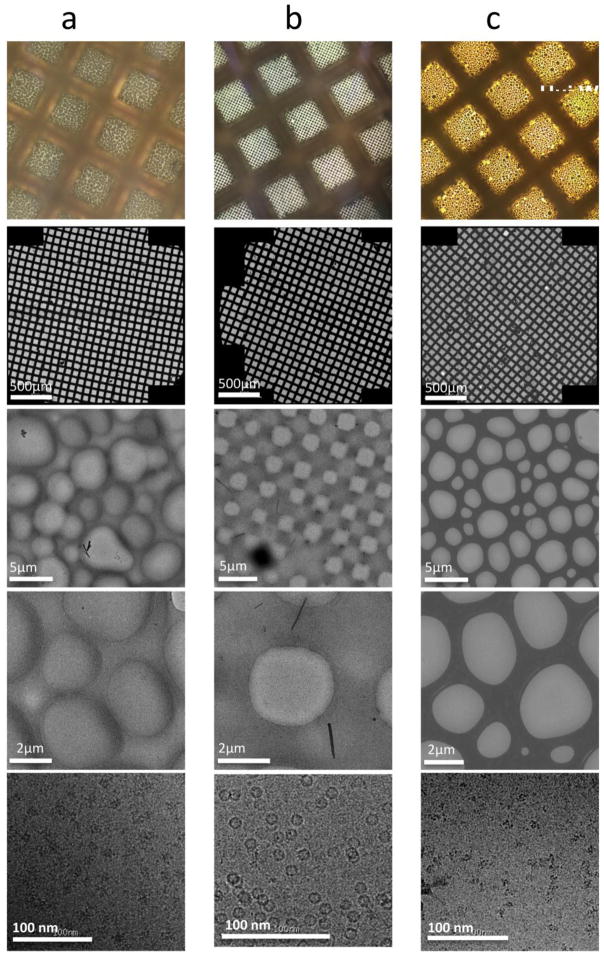

We have used the nanowire grids to vitrify a wide variety of samples including Apoferritin, 20S proteasome, 70S E. Coli ribosome, hemagglutinin, aldolase, IgG antibody, HIV trimer complexes, membrane proteins in nanodiscs, insulin receptors, and glutamate dehydrogenase. A few of these are illustrated in Figure 2 and other examples are provided in the companion paper describing the Spotiton instrument.

Supplementary Material

Supplementary videos: (V1) Movie of a carbon substrate on a Cu/Rh nanowire grid imaged at a 45° tilt angle. (V2) Movie of a gold substrate on Cu/Rh nanowire grid imaged at a 45° tilt angle.

Figure 3.

Self-wicking nanowire grids can be made using either lacey or patterned substrates composed of either carbon or gold. Left column is an SEM image; rows are TEM images at increasing magnifications. (a) Lacey carbon film used to vitrify HIV trimer complexes. (b) Patterned carbon film used to vitrify Apoferritin. (c) Lacey gold film used to vitrify insulin receptor-insulin complexes.

Acknowledgments

The work presented here was conducted at the National Resource for Automated Molecular Microscopy located at the New York Structural Biology Center, supported by grants from the NIH (GM103310, OD019994) and the Simons Foundation (349247). The authors would like to acknowledge the entire staff of the Simons Electron Microscopy Center at the New York Structural Biology Center (New York, NY) for help and technical support.

Footnotes

Publisher's Disclaimer: This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customers we are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, and review of the resulting proof before it is published in its final form. Please note that during the production process errors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

References

- Fukami, Adachi A new method of preparation of a self-perforated micro plastic grid and its application. J Electron Microsc (Tokyo) 1965;14:112–8. [PubMed] [Google Scholar]

- Jain T, Sheehan P, Crum J, Carragher B, Potter CS. Spotiton: a prototype for an integrated inkjet dispense and vitrification system for cryo-TEM. Journal of structural biology. 2012;179:68–75. doi: 10.1016/j.jsb.2012.04.020. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Razinkov I, Dandey V, Wei H, Zhang Z, Melnekoff D, Rice WJ, Wigge C, Potter CS, Carragher B. A new method for vitrifying samples for cryoEM. Journal of structural biology. 2016;195:190–198. doi: 10.1016/j.jsb.2016.06.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Russo CJ, Passmore LA. Ultrastable gold substrates: Properties of a support for high-resolution electron cryomicroscopy of biological specimens. Journal of structural biology. 2016;193:33–44. doi: 10.1016/j.jsb.2015.11.006. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Marr CR, Benlekbir S, Rubinstein JL. Fabrication of carbon films with 500nm holes for cryo-EM with a direct detector device. J Struct Biol. 2014;185:42–47. doi: 10.1016/j.jsb.2013.11.002. https://doi.org/10.1016/j.jsb.2013.11.002. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Supplementary Materials

Supplementary videos: (V1) Movie of a carbon substrate on a Cu/Rh nanowire grid imaged at a 45° tilt angle. (V2) Movie of a gold substrate on Cu/Rh nanowire grid imaged at a 45° tilt angle.