Table 1. Suzuki–Miyaura coupling of various aryl halides using PdNP@3a and Pd(PPh3)4 a , b .

| Entry | Aryl halide | Product | Yield [%] |

|

| PdNP@3a | Pd(PPh3)4 | |||

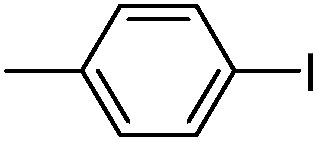

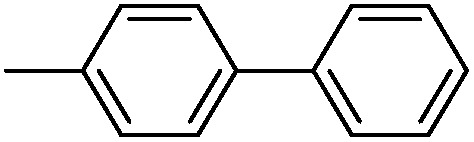

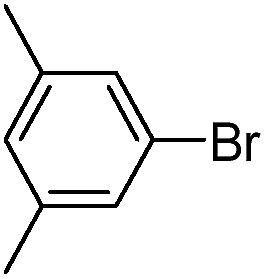

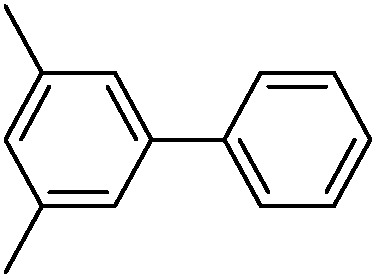

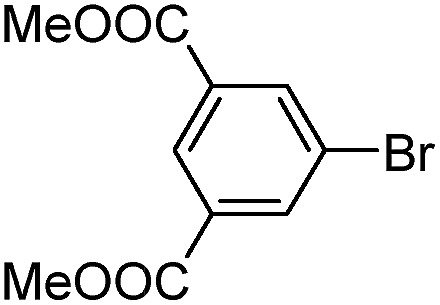

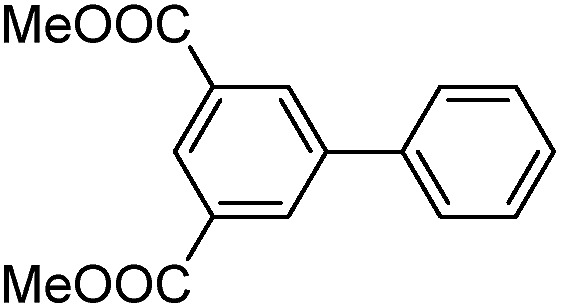

| 1 |

|

|

99 | 86, (99 c , 98 d , 22 e ) |

| 2 |

|

|

>99 | 81 |

| 3 |

|

|

96 | 85 |

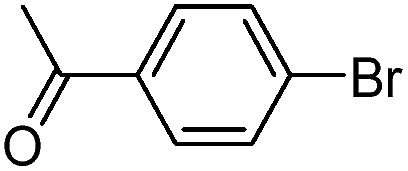

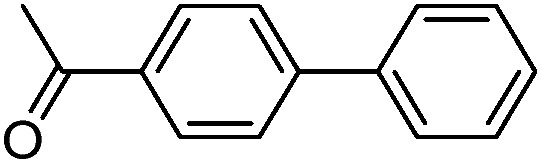

| 4 |

|

|

>99, >99 f | 78, 40 f |

| 5 |

|

|

>99 | 73 |

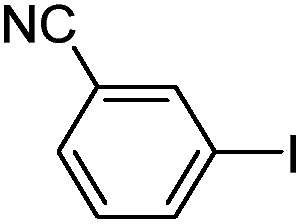

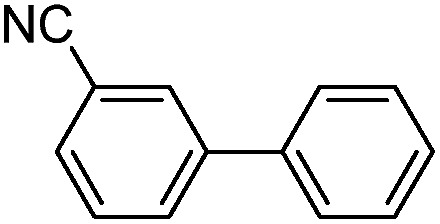

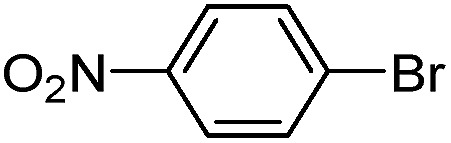

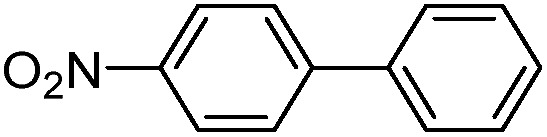

| 6 g |

|

|

99 ± 0.4 | 75, (78 c , 72 d , 20 ± 2.4 e ) |

aReaction conditions: aryl halide (0.057 mmol), phenylboronic acid (0.087 mmol), Na2CO3 (0.17 mmol), Pd catalyst (0.57 μmol, 1.0 mol%).

bYields are based on 1H NMR analysis of the crude products.

cFor Pd(PPh3)2Cl2 catalyst.

dFor Pd2(dba)3.

eFor Pd/C (5%).

fAfter exposure of the catalyst to air for 2.5 h.

g5 repeats with a standard deviation for both PdNP@3a and Pd/C (5%).