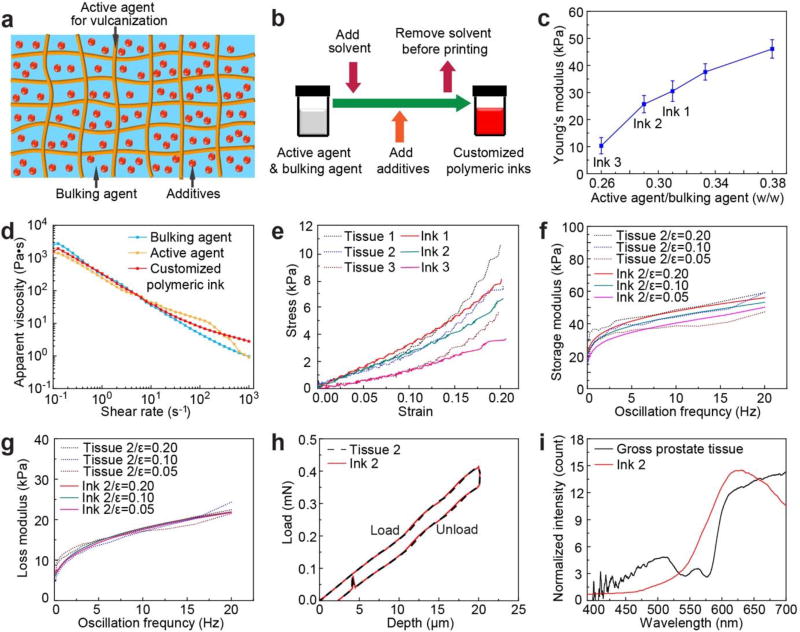

Figure 2.

Design and development of customized polymeric inks based on patient-specific prostate tissue data, and resulting ink fidelity with physical properties of the tissue. a) Schematic of the composite structure of the customized polymeric inks. b) Preparation procedure for the customized polymeric inks. c) A plot of prime component weight ratios vs. Young’s moduli for the polymeric inks. d) Log-log plots of apparent viscosity versus shear rate for a customized polymeric ink (including its constituent components) used for printing the prostate model. e) Static compression fidelity via stress-strain curves between different patient prostate tissue samples (Tissues 1–3) and printed samples of customized polymeric inks (Ink 1, 2, 3). f) Dynamic compression fidelity of storage modulus between a patient prostate tissue sample (Tissue 2) and a sample of customized polymeric ink (Ink 2) at frequencies of 0.1–20 Hz and strains of 0.05, 0.10, and 0.20. g) Dynamic compression fidelity of loss modulus between a patient prostate tissue (Tissue 2) and a sample of customized polymeric ink (Ink 2) at frequencies of 0.1–20 Hz and strains of 0.05, 0.10, and 0.20. h) Hardness fidelity via load-depth curves between a patient prostate tissue sample (Tissue 2) and a sample of customized polymeric ink (Ink 2). i) Optical fidelity via reflection curves between patient prostate gross tissue and a customized polymeric ink (Ink 2).