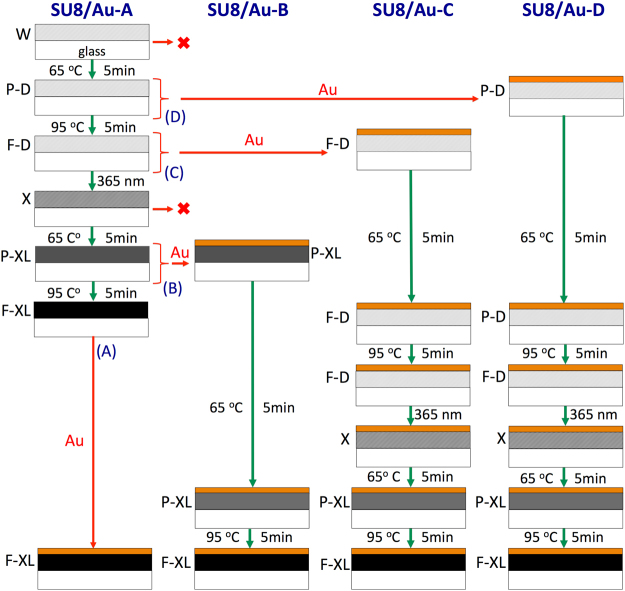

Figure 3.

Schematic showing conventional protocol for preparing Au-coated SU8 on glass plus several variants employed in this work. In the conventional procedure (A) SU8 is first deposited onto a glass substrate from solution, typically by spin-coating; the film is dried and solidified by heating to 65 °C, and then to 95 °C; it is then cooled to room temperature (RT) and exposed using 350–400 nm UV radiation to initiate photo-acid generation; it is then heated again to 65 °C, and then to 95 °C to induce complete cross-linking; and finally it is cooled to room temperature for metal deposition under vacuum. In the conventional approach (A), Au deposition occurs onto fully cross-linked SU8 at the final stage directly after the second 95 °C heating stage. In the variant methods, Au deposition occurs onto partially cross-linked SU8 at earlier stages in the process, either after the first 65 °C heating stage (D), after the first 95 °C heating stage (C), or after the second 65 °C heating stage (B). In cases (B) and (D), where gold deposition takes place after a 65 °C heating stage, an additional 65 °C heating stage is added prior to the 95 °C stage to avoid cracking the film. Uncoated SU8 films were prepared by carrying out the procedures up to (but not including) the point of gold deposition. The condition of the film at each stage of processing is indicated by the black lettering: “W” denotes a wet film containing significant residual solvent; “P-D” denotes a partially dried film containing some residual solvent; “F-D” denotes a fully dried film, containing minimal residual solvent; “X” denotes a UV-exposed film; “P-XL” denotes a partially cross-linked film; and “F-XL” denotes a full cross-linked film.