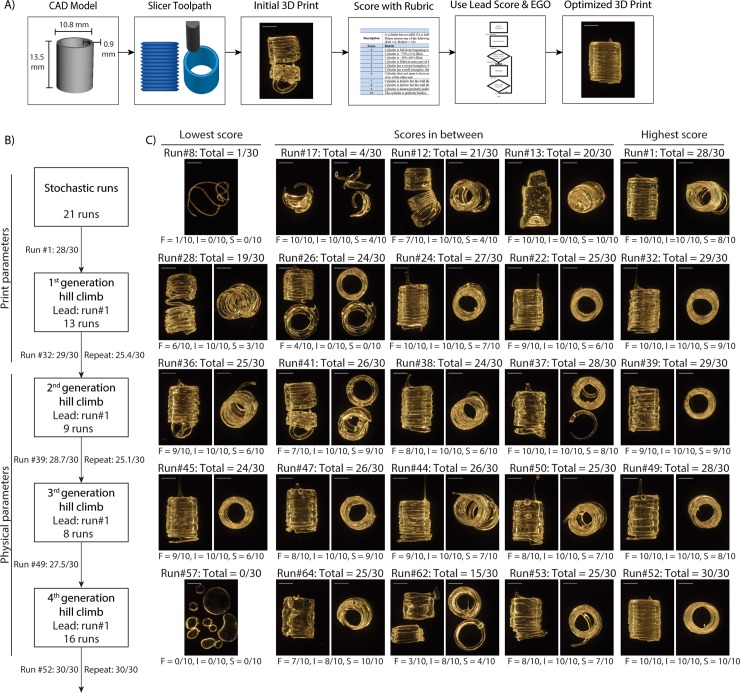

Fig 3. Applying the EGO strategy to 3D printing of calibration cylinders.

(A) Overview of the steps to optimize the cylinder (CAD model) that is imported in to the slicing software to determine the path of the extruder (slicer toolpath). The resulting product (initial 3D print) is assessed (score with rubric) and the fittest run is used as lead in the hill climb (use lead score and EGO) to reach full score (optimized 3D print). (B) Summary of the second step, hill climb, of the EGO strategy for calibration cylinders detailing the total number of runs and the lead run in each within the designated parameter space. (C) Representative images of PDMS 3D prints in each generation with the score for each response variables (layer fusion = F, infill = I, stringiness = S) and the total (lowest, highest, in between). Scale bars are 5 mm.