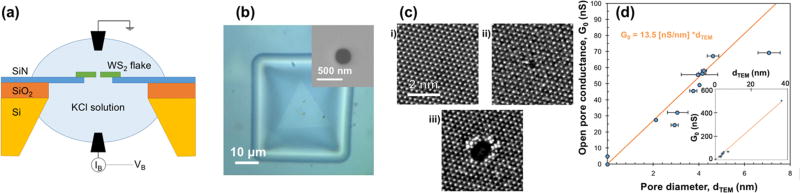

Figure 4.

Fabrication and characterization of WS2 nanopore devices. (a) Schematic of the nanopore device setup. The WS2 flake (green) is suspended on a 200–500 nm FIB hole in a 50 nm thick and 50 µm × 50 µm dimensions SiNx (deep blue) window, fabricated on a SiO2/Si (orange/yellow) wafer. A 1 or 3 M KCl solution (light blue) is separated by the nanopore in the WS2 flake. A bias voltage (VB) is applied across the nanopore using Ag/AgCl electrodes (black), and the ionic current through the nanopore (IB) is measured. (b) Optical image of a triangular WS2 flake on a SiNx window with a FIB hole. (Inset) Scanning electron microscopy image of a 300 nm FIB hole. (c) AC-HRSTEM image of (i) an undamaged suspended WS2 membrane, (ii) a 0.3 nm nanopore, and (iii) a 1.3 nm nanopore drilled with accelerating voltage of 80 kV. (d) Plot of open pore conductance of WS2 nanopores with the corresponding nanopore diameter. Inset shows the plot over a larger dTEM range. The solution conductivity was calculated by fitting the equation for 2D nanopores (G0 = σdTEM) and found to be 13.5 ± 0.3 S/m. The nanopore diameter was calculated from the corresponding STEM image by defining a threshold for pixel intensities and selecting the pixels within that range in the vicinity of the pore in ImageJ software. This was repeated multiple times for a single pore, and the standard deviation was taken as the measurement error. Standard deviations in the slope of IB vs VB plots for each nanopore were used as the error in open pore conductance, which are very small and lie within each data point area.