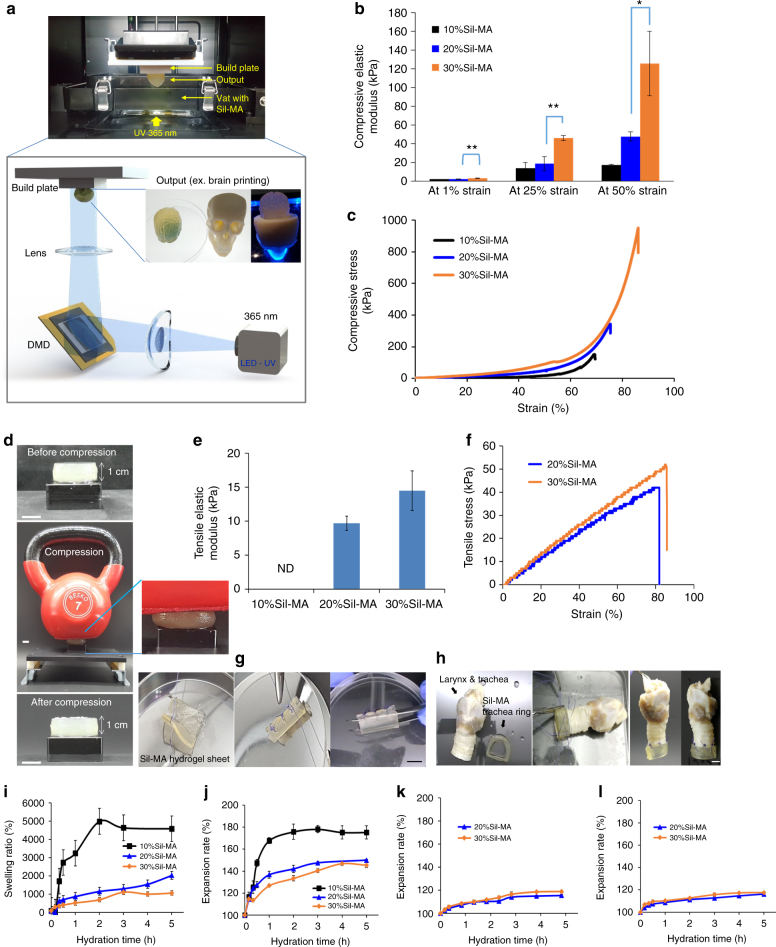

Fig. 3.

Physical properties of Sil-MA hydrogel. a Schematic diagram of DLP bioprinting procedure using Sil-MA. Sil-MA-added LAP was printed in a layer-by-layer style with DLP printer. Herein, the desired pattern was designed through CAD software and was sliced to a layer file before transferring it to the DLP system. DMD digital micromirror device. b–d Compression test for Sil-MA hydrogel with varied Sil-MA contents. b Compressive elastic modulus of Sil-MA hydrogel at different percentage strains. Significant differences are presented. *p < 0.05 and **p < 0.005 (two-sample t-test). c Representative compressive stress–strain curve and d the Sil-MA hydrogel was compressed by a kettle bell (7 kg) for 3 min and recovered hydrogel’s initial shape after it was removed. e–h Tensile stress for Sil-MA hydrogel. e Tensile elastic modulus of Sil-MA hydrogel at 50% strain and f representative tensile stress–strain curve of Sil-MA hydrogel. g Suturing of folded lumen structure of 3D-printed Sil-MA membrane and h trachea end-to-end anastomosis of dog’s larynx and trachea using Sil-MA 3D DLP-printed hydrogel. Scale bar indicates 1 cm. i–l Swelling properties. i Water uptake of Sil-MA powder. Volume expansion rate of DLP product in j water, k medium, and l PBS (pH 7.4). Data are presented as mean ± s.d. The black line (/bar), blue line (/bar), and orange line (/bar) indicate 10%, 20%, and 30% of Sil-MA hydrogel, respectively. Each assay was conducted in triplicate