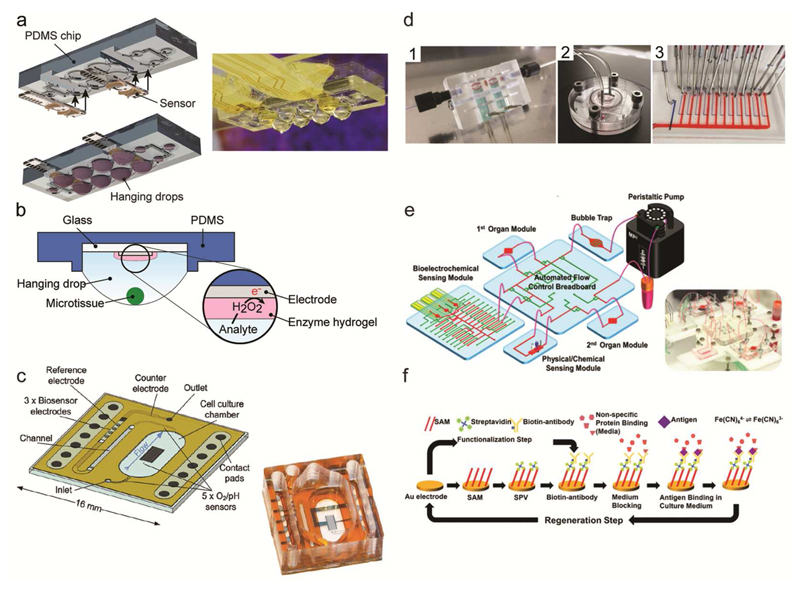

Figure 3.

Electrochemical biosensors. (a) Schematic view and photograph of sensors integrated in the hanging-drop device for measuring the metabolism of 3D microtissues. The device has been assembled by inserting sensor modules directly into the microfluidic substrate. Adapted with permission from Misun et al., Microsystems and Nanoeng. 2, 16022.70 Copyright 2016. (b) Schematic view showing the location of the biosensor electrode at the ceiling of the hanging drop substrate and the position of the 3D microtissues at the liquid-air interface of the hanging drop. The inset shows the functional enzyme layer on the electrode and the working principle of an enzyme-based biosensor. Adapted with permission from Misun et al.70 (c) Schematic view and photograph of a transparent, integrated microfluidic sensor chip, which features multiple electrochemical sensors. Adapted from Weltin et al. 136 with permission from the Royal Society of Chemistry. (d) Separate biosensor module for glucose and lactate detection (1). Bioreactor for a liver-on-chip culture, which is connected to the sensor unit and to a microfluidic switchboard (2). The microfluidic switchboard, containing flow channels (red) and control channels (blue) (3). Adapted with permission from Bavli et al., PNAS, E2232-E2240.140 (e) Schematic view of the modular MPS by Zhang et al.9 featuring several fluidically interconnected components, including two cell-culturing chambers, a peristaltic pump, a bubble trap, a control breadboard, medium reservoirs and different electrochemical sensors. The photograph shows the complete MPS. (f) Example of electrode functionalization, electrochemical readout and sensor regeneration of an electrochemical immunosensor. Adapted with permission from Zhang et al., PNAS, E2293-E2302.9