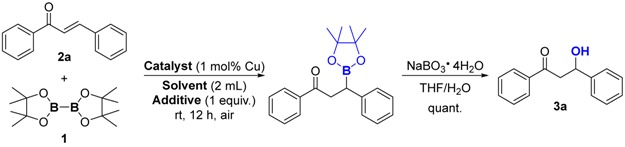

Table 1.

Optimization of the reaction conditions a.

| Entry | Catalyst | Solvent | Additive | Yield(%) b |

|---|---|---|---|---|

| 1 | CP@Cu NPs | toluene | -- | NR c |

| 2 | CP@Cu NPs | Et2O | -- | NR c |

| 3 | CP@Cu NPs | THF | -- | trace |

| 4 | CP@Cu NPs | toluene | MeOH | 7 |

| 5 | CP@Cu NPs | Et2O | MeOH | 6 |

| 6 | CP@Cu NPs | THF | MeOH | 32 |

| 7 | CP@Cu NPs | acetone | MeOH | 66 |

| 8 | CP@Cu NPs | MeOH | -- | 70 |

| 9 d | CP@Cu NPs | THF/H2O = 2/1 | -- | 75 |

| 10 d | CP@Cu NPs | MeOH/H2O = 2/1 | -- | 89 |

| 11 d | CP@Cu NPs | acetone/H2O = 2/1 | -- | 91 |

| 12 d | CP@Cu NPs | acetone/H2O = 4/1 | -- | 95 |

| 13 d | CP@Cu NPs | acetone/H2O = 1/4 | -- | 76 |

| 14 d | -- | acetone/H2O = 4/1 | -- | NR c |

| 15 d,e | CS@Cu | acetone/H2O = 4/1 | -- | 35 |

| 16 d,f | CS/PEG@Cu NPs | acetone/H2O = 4/1 | -- | 75 |

| 15 d,g | CP@Cu NPs | acetone/H2O = 4/1 | -- | 89 |

| 16 c,h | CP@Cu NPs | acetone/H2O = 4/1 | -- | 94 |

a Reaction conditions: substrate 2 (0.2 mmol), B2(pin)2 1 (1.2 equiv), catalyst (1 mol % Cu loading), Solvent (2 mL), room temperature, air, 12h; b Isolated yield of product; c NR = no reaction; d Ratio of volume to volume; e Chitosan supported Cu was used; f Chitosan/poly (ethylene glycol) composite film supported Cu nanoparticles were used; g 0.5 mol % Cu loading was used; h Performed under Ar atmosphere.