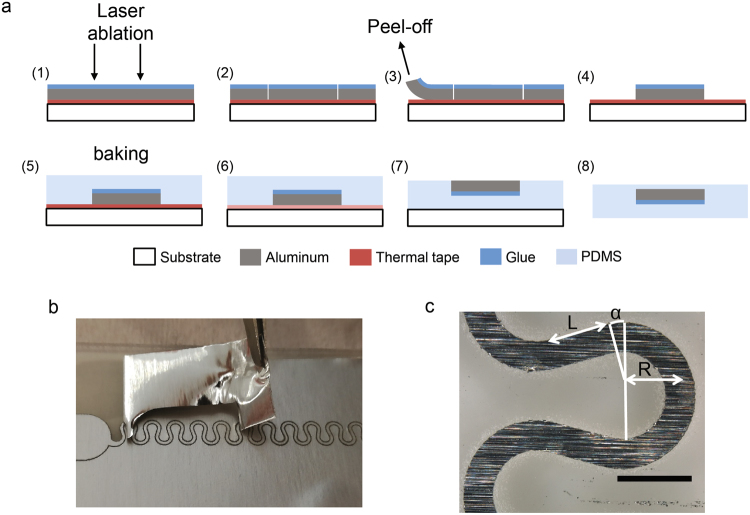

Figure 1.

Fabrication and characterisation of stretchable interconnections. (a) Schematic of the preparation process of the metallic line based on the laser cutting of metallic foil attached on a thermal release tape. Once patterned and peeled off, the line is encapsulated in PDMS. The final device consists of aluminium tape sandwiched within PDMS layers, which offer a high degree of stretchability. (b) Illustration of the peel-off process. The unwanted regions of metal are either manually removed or removed by the laser to have a process compatible with conventional thin-film microelectronics fabrication. (c) The sweep on the different parameters is illustrated: the angle α, the length of the connections L between two arcs of the circles and R, the radius of the arc of a circle. The aluminium thickness is 50 µm and the width of the lines is 400 µm. The scale bar represents 1 mm.