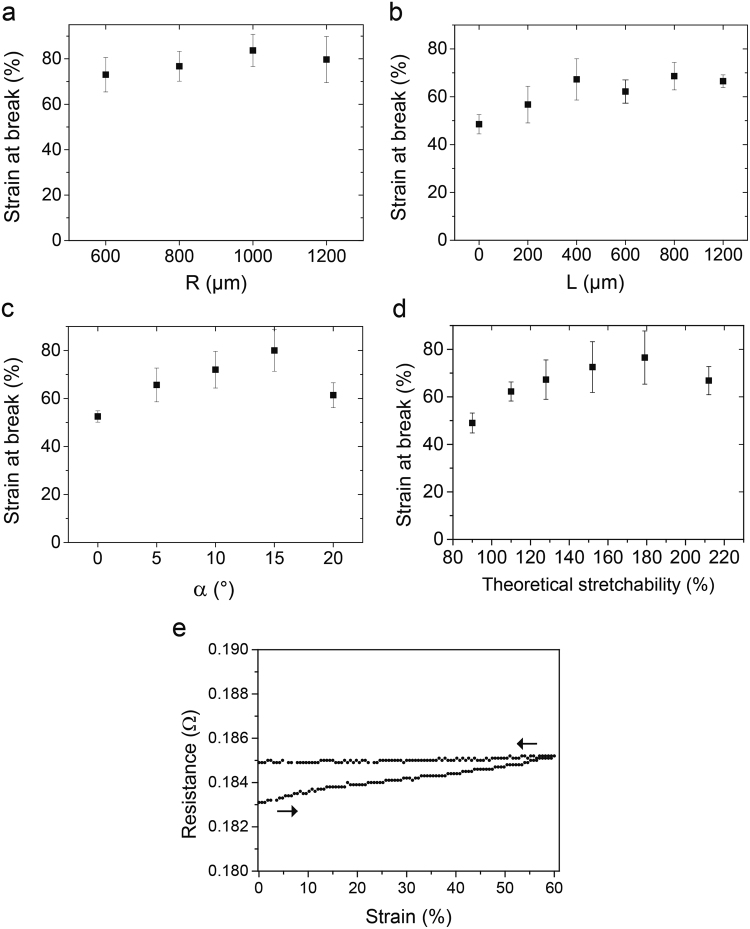

Figure 2.

Optimisation of the stretchability of the interconnections. (a–c) Experimental strain at break of the line for each parameter over 10 samples. The strain is applied at a speed of 100 µm/s and a measurement of the electrical resistance is taken at every 0.5% strain with a Keithley® using a four-terminal measurement setup. (d) Compilation of the previous results representing the strain at break as a function of the calculated theoretical stretchability which is equivalent to the maximum strain the line can undergo before becoming straight. It is possible to design stretchable interconnections with an average point of rupture of 70%. (e) Example of electrical/mechanical characterisation of a line with the resistance as a function of the strain up to 60% for a line with width = 400 µm, α = 15°, L = 800 µm, R = 800 µm, metal thickness = 50 µm for a total length of the serpentines of approximately 95 mm. Distance between the jaws is 40 mm. The strain is applied up to 60% and then goes back to 0%. There is an increase of 1% in the resistance while stretching due to small strain in the metal but afterwards, the resistance stays constant during relaxation from 60 to 0%.