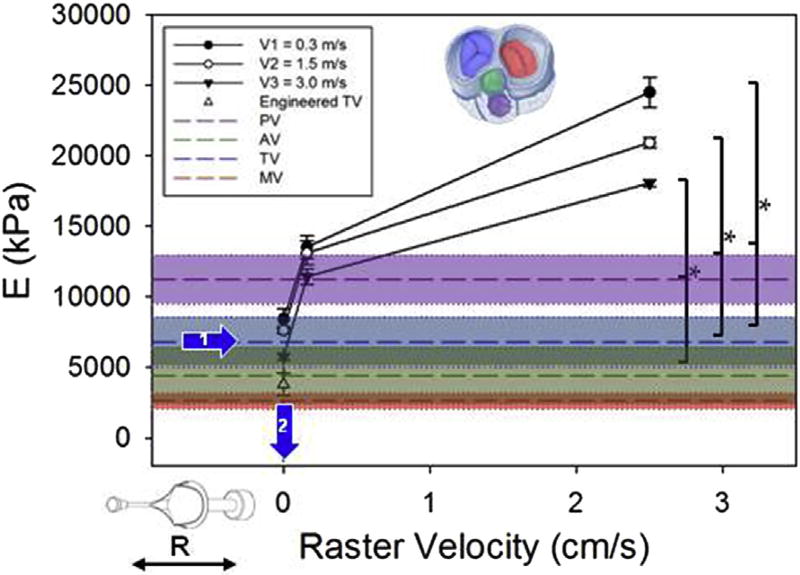

Fig. 6. DCD process control of engineered valve bending mechanics.

Valve leaflet bending modulus was calculated for different values of mandrel tangential velocities (0.3, 1.5, 3 [m/s]) and rastering velocities (0, 0.16, 2.5 [cm/s]) n = 3, mean ± sem. The rastering velocity dictated the bending rigidity over a range that included the rigidity measured in atrioventricular and outflow track valve leaflets (n ≥ 7 mean ± sem). The prescribed raster velocity (0 cm/s) to achieve physiologic bending rigidity resulted in an engineered valve with rigidity below the native tricuspid valve tissue, although due to the shape of the rigidity vs. raster velocity curve in this area there is the potential for large changes in rigidity with small changes in raster velocity. Native valve leaflet thickness, elastic modulus (with AV and MV elastic moduli significantly < PV) and resulting global bending rigidity are reported in Fig. 7.