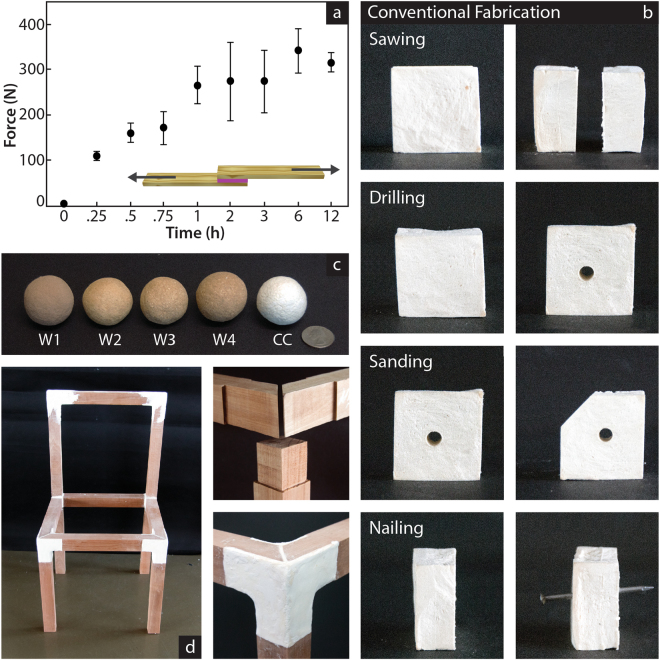

Figure 3.

Additive properties of fungus-like materials and their use in woodworking techniques. (a) Adhesion force with respect time following the standard test of adhesion (ASTM D5868) with respect to time. Full strength is achieved after 1 hour, from that point 21 mg of dry FLAM covering an area of 9.3 × 9.3 mm holds the equivalent to 29.02 ± 6.35 kg. This ability of the material to attach to cellulosic composites (included itself) enables its use in additive manufacturing. (b) Use of FLAM in conventional woodworking techniques. A 4 × 4 × 4 cm FLAM cube is sawn in two halves, one of the halves is then drilled and then sanded down to remove one of the corners. A nail is hammered through the other half. (Supplementary Movie 2) (c) Composites made with different sources of cellulosic materials. Samples one to four (from left) are made of wood byproducts of different qualities and sources, while the right sphere (labeled “CC”) is made of pure cellulose (Supplementary Tables 1 and 2). (d) Use of the material in combination with pieces of solid wood to produce a functional chair. All pieces are attached uniquely by the FLAM material. The fungus-like biomimetic material can be casted, 3D printed, molded but also modified using regular woodworking techniques (Supplementary Fig. 4).