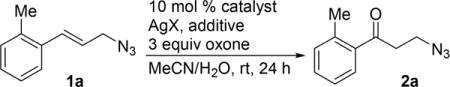

Table 1.

Optimization of the Wacker Oxidationa

| ||||

|---|---|---|---|---|

|

| ||||

| entry | [Pd] | AgX | additive(s) | yieldb (%) |

| 1 | Pd(PhCN)2Cl2 | 0 | ||

| 2 | Pd(PhCN)2Cl2 | AgOTf | 33 | |

| 3 | Pd(PhCN)2Cl2 | AgSbF6 | 39 | |

| 4 | Pd(PhCN)2Cl2 | AgBF4 | 18 | |

| 5 | Pd(PhCN)2Cl2 | AgNO3 | 40 | |

| 6 | Pd(PhCN)2Cl2 | AgNO3 | BQ | 73 |

| 7c | Pd(MeCN)4(BF4)2 | BQ, KNO3 | 51 | |

| 8 | Pd(MeCN)4(BF4)2 | BQ | 59 | |

| 9 | Pd(MeCN)4(BF4)2 | BQ, KNO3 | 71 | |

| 10d | Pd(PhCN)2Cl2 | AgNO3 | BQ | 67 |

| 11e | Pd(PhCN)2Cl2 | AgNO3 | BQ | 80 |

Reaction conditions: substrate (60 μmol), naphthalene standard (12 μmol), [Pd] (6 μmol, 10 mol %), AgX (15 μmol, 25 mol %), benzoquinone (12 μmol, 20 mol %), Oxone (180 μmol, 3 equiv), water (50 μL), MeCN (400 μL), under air, room temperature.

Conversion and yield were determined by calibrated GC−FID analysis. Reactions were run in duplicate, and the average value is reported.

Reaction was conducted with 1.2 equiv of benzoquinone and no Oxone.

Reaction was run using double the volume of water (100 μL).

Oxone was added portionwise.