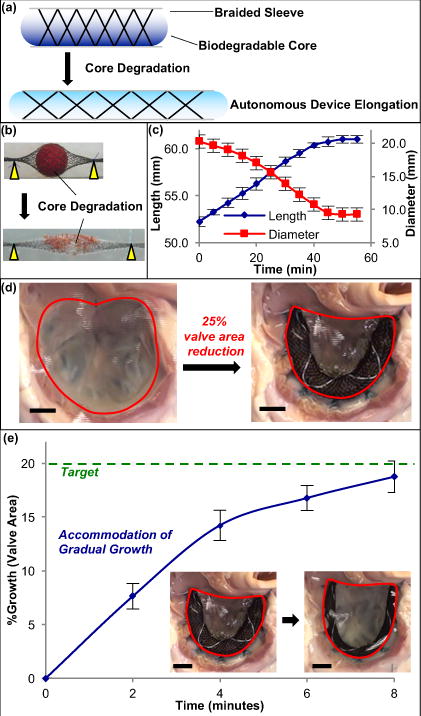

Figure 1. Growth-accommodating device concept – accelerated degradation model of biaxially braided sleeve and biodegradable core.

a, Schematic of degradable polymer core (blue) placed inside braided sleeve to control sleeve diameter, coupling inner polymer degradation to braided sleeve (and overall device) elongation. b, Dissolvable spherical sucrose core (red) inside nitinol biaxial braid acts as degradable polymer surrogate. When submerged in water gradual core dissolution leads to gradual decrease in braided sleeve diameter and concomitant autonomous 1-D device elongation for long-bone orthopedic applications. c, Braided sleeve behavior & core degradation. Device elongation is gradual and reproducible, and is dependent upon core diameter change (n = 4, mean ± s.d.). d, En face view of tricuspid valve in isolated swine heart preparation. Annuloplasty using growth-accommodating ring prototype results in 25% reduction in valve area (877.2 ± 141.2 mm2 → 650.6 ± 55.3 mm2). e, Ring & valve growth. When placed in water, core dissolution enables braided sleeve elongation and gradual ring expansion, allowing for controlled heart valve growth to target valve area of 780 mm2 (20% growth) (n = 3, mean ± s.d.). Scale bars = 10 mm.