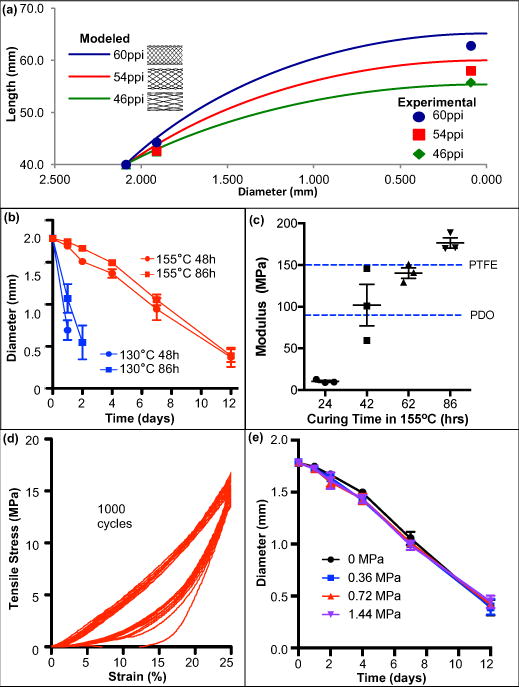

Figure 2. Biaxially braided sleeve, inner polymer, and overall device characterization.

a, Braid elongation (modeled vs. experimental). Graphical representation of length-diameter relationship for biaxially braided sleeves. Changing braid pitch (defined by picks-per-inch (PPI)) creates unique elongation profiles for device tunability. Modeled braided sleeve behavior (curves) accurately reflects actual sleeve behavior (experimentally measured lengths:

,

,

,

,

) across range of braid profiles. b, ESPGS degradation profile under accelerated conditions for different polymer curing temperatures & durations. Degradation rate is significantly influenced by curing temperature (n = 3, mean ± s.d.). c, Young’s modulus of device with different PGS cores. Overall device modulus is affected by inner polymer curing. Increasing curing duration and curing at 155°C results in increased device strength. Device prototypes with 86-hour ESPGS have greater Young’s Modulus than commercially available surgical sutures (e.g. PTFE, polydioxanone (PDO)) (n = 3, mean ± s.d.). d, Representative cyclic tensile testing demonstrates no evidence of device fatigue following 1000 cycles (n = 3). e, ESPGS degradation profile under accelerated conditions with varying tensile stresses applied to overall device. Degradation rate is not significantly influenced by applied stress. (n = 3, mean ± s.d.)

) across range of braid profiles. b, ESPGS degradation profile under accelerated conditions for different polymer curing temperatures & durations. Degradation rate is significantly influenced by curing temperature (n = 3, mean ± s.d.). c, Young’s modulus of device with different PGS cores. Overall device modulus is affected by inner polymer curing. Increasing curing duration and curing at 155°C results in increased device strength. Device prototypes with 86-hour ESPGS have greater Young’s Modulus than commercially available surgical sutures (e.g. PTFE, polydioxanone (PDO)) (n = 3, mean ± s.d.). d, Representative cyclic tensile testing demonstrates no evidence of device fatigue following 1000 cycles (n = 3). e, ESPGS degradation profile under accelerated conditions with varying tensile stresses applied to overall device. Degradation rate is not significantly influenced by applied stress. (n = 3, mean ± s.d.)