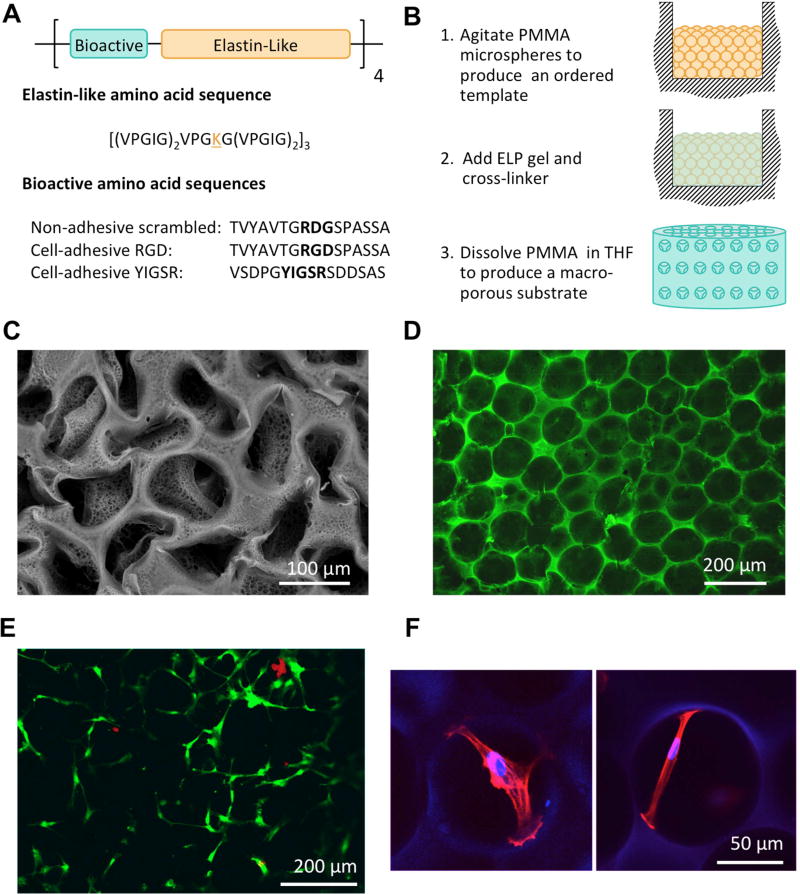

Figure 1.

Porous ELP substrate design, fabrication and biocompatibility. A) ELP peptide sequences were designed with modular repeats of bioactive and elastin-like regions. The bioactive domains used in this study were an extended RGD adhesive sequence from fibronectin, an extended YIGSR adhesive sequence from laminin and a non-adhesive scrambled RDG sequence. B) A schematic of the sacrificial templating technique used to fabricate porous ELP substrates. C) An SEM image of an ELP substrate illustrating the complete removal of PMMA microspheres from the structure. The partial collapse of the structure is due to necessary dehydration of the sample prior to imaging. D) A confocal image of the hydrated pore structure of the ELP substrates. E) A representative image of live (green) and dead (red) hMSCs 24 hours post seeding illustrating that cell viability on ELP substrates is not compromised by the sacrificial templating technique. F) hMSC attachment spans across pores within the porous ELP substrates (actin = red, nucleus/ELP = blue).