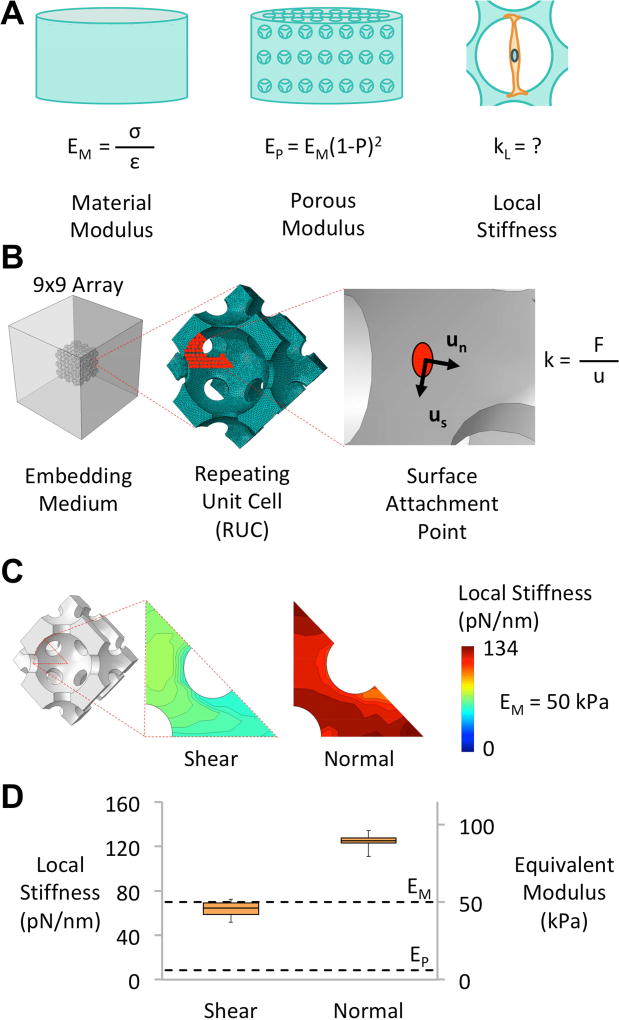

Figure 3.

The computational framework used to determine local stiffness values within porous substrates. A) Material modulus can be determined through uniaxial compression testing, while the modulus of the porous substrate can be derived from the porosity (P) and the material modulus using the Gibson-Ashby cellular solid model.46 However, currently no relationship exists to define the local stiffness at the pore surfaces. B) The model considered attachment points on a 1/16 symmetry of the repeating unit cell. Unit micron displacements in both shear and normal orientations (Un & Us) were then applied to each attachment point and the stiffness (k) was determined based on the reaction force (F) that was generated. C) The spatial variation of shear and normal stiffness across 1/16 of the FCC repeating unit scaffold surface. The stiffness values presented are representative of a substrate with a material modulus of 50 kPa. D) A box plot displaying both the local stiffness and the equivalent modulus presented by a 60 % porous substrate with a material modulus of 50 kPa. The dashed lines signify upper- and lower-bound modulus values, which represent the material and porous modulus of the substrate, respectively.