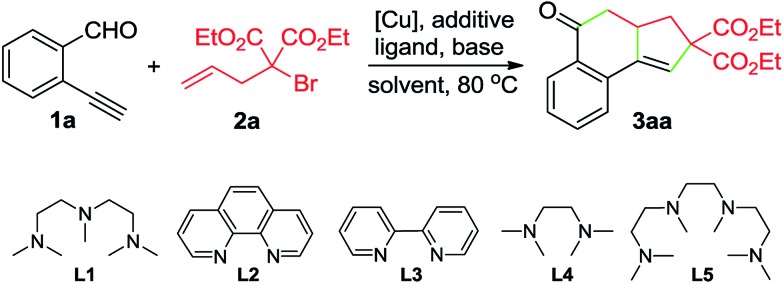

Table 1. Optimization of the reaction conditions a .

| ||||||

| Entry | [Cu] | Ligand | Additive | Base | Solvent | Yield (%) |

| 1 | CuBr | L1 | — | K2CO3 | MeCN | 42 |

| 2 | CuBr2 | L1 | DEAD | K2CO3 | MeCN | 36 |

| 3 | Cu(acac)2 | L1 | DEAD | K2CO3 | MeCN | 83 |

| 4 | Cu(OAc)2 | L1 | DEAD | K2CO3 | MeCN | 86 |

| 5 | Cu(OAc)2 | L1 | — | K2CO3 | MeCN | 61 |

| 6 | Cu(OAc)2 | L2 | DEAD | K2CO3 | MeCN | 52 |

| 7 | Cu(OAc)2 | L3 | DEAD | K2CO3 | MeCN | 34 |

| 8 | Cu(OAc)2 | L4 | DEAD | K2CO3 | MeCN | 75 |

| 9 | Cu(OAc)2 | L5 | DEAD | K2CO3 | MeCN | 80 |

| 10 | Cu(OAc)2 | L1 | AIBN | K2CO3 | MeCN | 62 |

| 11 | Cu(OAc)2 | L1 | V65 | K2CO3 | MeCN | 65 |

| 12 | Cu(OAc)2 | L1 | DEAD | Cs2CO3 | MeCN | 47 |

| 13 | Cu(OAc)2 | L1 | DEAD | DBU | MeCN | 21 |

| 14 | Cu(OAc)2 | L1 | DEAD | K2CO3 | THF | Trace |

| 15 | Cu(OAc)2 | L1 | DEAD | K2CO3 | PhMe | Trace |

| 16 | Cu(OAc)2 | L1 | DEAD | K2CO3 | DMF | 14 |

a Reaction conditions: 1a (0.25 mmol), 2a (0.30 mmol), [Cu] (10 mol%), ligand (20 mol%), additive (20 mol%), base (0.25 mmol), solvent (3 mL), under N2 80 °C, 10 h. Yields of the isolated products are given.