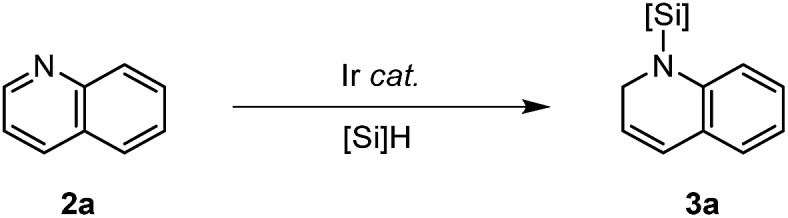

Table 1. Optimization of the 1,2-hydrosilylation of quinoline 2a a .

| ||||||

| Entry | Ir catalyst (mol%) | Silane (equiv.) | Solvent | T (°C) | Time (h) | Yield b (%) |

| 1 | [Ir(coe)2Cl]2 (1.4) | Et2SiH2 (1.5) | CDCl3 | 25 | 5 | 62 |

| 2 | [Ir(coe)2Cl]2 (1.4) | Et2SiH2 (1.5) | THF-d8 | 25 | 15 | 69 |

| 3 | [Ir(coe)2Cl]2 (1.4) | Et2SiH2 (1.5) | C6D6 | 25 | 4 | 85 |

| 4 | [Ir(coe)2Cl]2 (1.4) | Et2SiH2 (1.5) | Hexane-d14 | 25 | 4 | 99 |

| 5 | [Ir(coe)2Cl]2 (1.4) | Et2SiH2 (1.5) | Neat | 25 | 2 | 99 |

| 6 | [Ir(coe)2Cl]2 (1.4) | Et2SiH2 (1.5) | C6D6 | 55 | 1 | 99 |

| 7 c | [Ir(coe)2Cl]2 (1.4) | Et2SiH2 (1.5) | C6D6 | 55 | 1 | 99 |

| 8 | [Ir(coe)2Cl]2 (0.1) | Et2SiH2 (1.5) | C6D6 | 55 | 60 | 99 |

| 9 | [Ir(coe)2Cl]2 (0.1) | Et2SiH2 (3.0) | Neat | 55 | 60 | 99 |

| 10 | [Ir(coe)2Cl]2 (4.2) | Et3SiH (1.5) | C6D6 | 85 | 15 | <1 |

| 11 | [Ir(coe)2Cl]2 (4.2) | Me2PhSiH (1.5) | C6D6 | 55 | 15 | <1 |

| 12 | [Ir(coe)2Cl]2 (4.2) | Ph2SiH2 (1.5) | C6D6 | 55 | 15 | <1 |

| 13 | [Ir(coe)2Cl]2 (1.4) | PhMeSiH2 (1.5) | C6D6 | 25 | 4 | 40 |

| 14 | [Ir(coe)2Cl]2 (1.4) | PhSiH3 (1.5) | C6D6 | 25 | 15 | 29 d |

| 15 | [Ir(cod)OMe]2 (1.4) | Et2SiH2 (1.5) | C6D6 | 25 | 4 | 61 |

| 16 | [Ir(cod)Cl]2 (1.4) | Et2SiH2 (1.5) | C6D6 | 25 | 4 | 58 |

aCarried out in a J-Young NMR tube with 2a (0.35 mmol, 1 equiv.), Et2SiH2 (1.5–3.0 equiv.) and [Ir(coe)2Cl]2 (0.1–4.2 mol%), either neat or in solvent (0.35 mL), under an argon atmosphere.

bYield of 3a determined using 1H NMR.

cPerformed in a reaction vial.

dUnidentified side products were also formed.