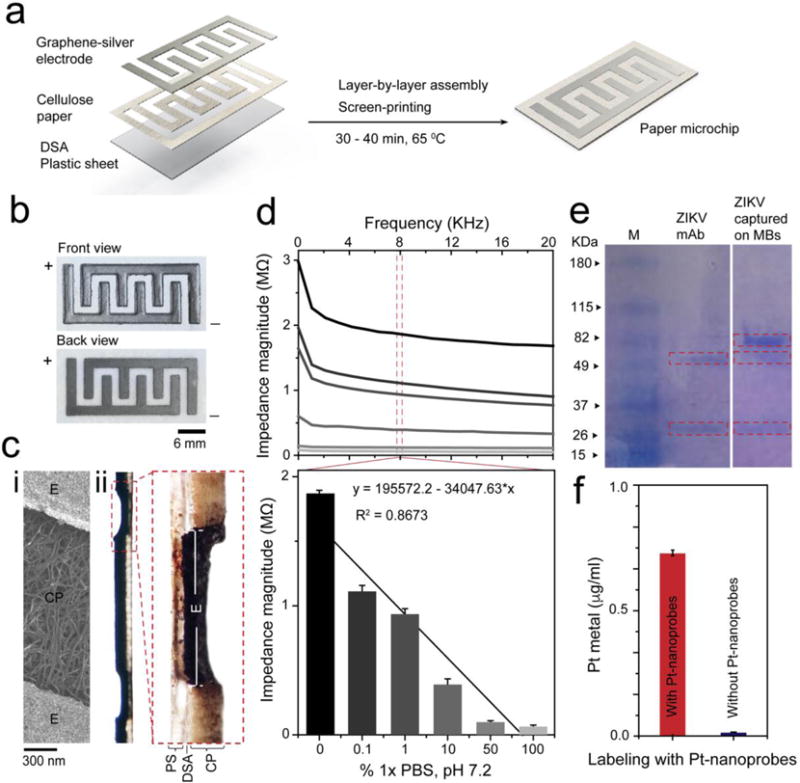

Figure 3. Paper microchip fabrication and ZIKV capture and labeling with Pt-nanoprobes.

(a) Paper microchip fabrication protocol. The chip is prepared with a layer of cellulose paper (0.34 mm thickness) added to the surface of a plastic sheet by a DSA. The electrode is screen-printed on the cellulose paper using graphene-silver nanocomposite ink and then dried for 30 – 40 min at 65 0C. (b) Digital image of the prepared cellulose paper microchip. (c) SEM of the surface of the paper microchip (i) and bright-field microscopy of transverse section of the paper chip (ii). CP is cellulose paper, DSA is double-sided adhesive, E is electrode and PS is plastic sheet. (d) Average impedance magnitude spectra over a range of frequencies up to 20 KHz for different dilutions of 1× phosphate-buffer saline (PBS), pH 7.2 on the developed paper microchip. Column chart shows the correlation between the impedance magnitudes of different 1×PBS dilutions measured at 8 KHz and 1 V. (e) SDS-PAGE shows different protein bands confirming the capture of ZIKV on magnetic beads (MB). (f) Pt metal weight measured by ICP-MS confirms the labeling of ZIKV particles captured on magnetic beads using Pt-nanoprobes.