Abstract

Tomato processing industry generates huge waste like tomato skin, seed, and pulp which creates environmental issues. Since tomato pomace contains bioactive compounds and pigments, present study was conducted to investigate the effect of tomato pomace addition on physicochemical characteristics and shelf-life stability of the developed bread and muffin. Refined flour was partially substituted with 35 and 40% tomato pomace in bread and muffin, respectively. Tomato pomace addition in bread and muffin was observed to significantly (p < 0.05) increase the dietary fiber, vitamin C, antioxidant activity and minerals (Na, K, Mg, Ca, Fe). The color parameters for bread and muffins were quantified in terms of L* (lightness), a* (redness/greenness) and b* (yellowness/blueness). There was an increase in a* and b*, while L* values decreased. Tomato based bread and muffin were found to possess softer texture as compared to control products. Microbial study has depicted the enhanced shelf-life of tomato based bread and muffin. Shelf life of preservative added tomato based bread was 8 days and muffins were 12 days. Tomato pomace could be a very useful commodity for incorporation into bread and muffin to have a complete nutritive food product.

Electronic supplementary material

The online version of this article (10.1007/s13197-018-3176-0) contains supplementary material, which is available to authorized users.

Keywords: Tomato pomace, By-product, Bread, Muffin, Nutrition, Shelf-life

Introduction

Now-a-days, foods are not only consumed to satisfy hunger and to provide nutrients to us but also to obstruct clinical diseases in order to enhance mental and physical well-being, qualitatively (Takachi et al. 2008). Recently, consumer demand for healthier food has activated for the development of bakery products with ingredients having functional properties beyond traditional nutrients (Bhat and Ahsan 2015). Tomato (Lycopersicon esculentum) is one of the most consumed vegetables worldwide in both form, fresh as well as processed products like tomato puree, paste, ketchup, juice, mainly (Pinela et al. 2012). Tomato is also one of the main source of minerals, vitamins and antioxidants (Adalid et al. 2010). Tomatoes have lycopene which is a major carotenoid and act as natural anticancer molecule (Rao and Agarwal 1999; Martínez-Hernández et al. 2016).

During the processing of tomatoes, the waste is just disposed and allowed to spoil which increases landfill costs and concerns about solid waste (Bhat and Ahsan 2015). Tomato industry generates large amount of by-products representing 10–30% of total processed tomatoes containing tomato seeds, peels and pulp (Rahmatnejad et al. 2009). These by-products are good source of functional compounds like phenolic compounds, fiber, and minerals and hence may be used in value added food products development because of their nutritional and functional properties (Knoblich et al. 2005). Tomato pomace generally contains high level of total dietary fiber, protein, fats and a good amount of ash (Majzoobi et al. 2011). Also, absence of anti-nutrient components has been reported in tomato pomace (Sogi et al. 2002; Del Valle et al. 2006). García et al. (2009) suggested to include dry tomato peel to raw and cooked hamburger. Alves et al. (2012) have used tomato pomace to provide productive protection against lipid oxidation in high-pressure processed minced chicken meat. Extrusion process-ability of barley flour with tomato pomace to produce sensory acceptable products has also been reported (Altan et al. 2008). Excellent nutritional properties of tomato pomace has generated an interest to develop bakery products. Bakery products like bread, muffins are the fast and convenient food based on wheat flour (Bhat and Ahsan 2015). Bread is the main source of carbohydrates in many parts of the world, especially in developing countries (Quail 2004).

In view of nutritional importance, we have developed bread and muffins by incorporation of tomato processing residues. The effect of addition of tomato pomace on nutritional properties, sensory, textural, and shelf-life stability of bread and muffin was conducted. The novel finding after incorporating tomato processing residue was improvement in nutritional content of developed bakery goods like vitamin C, antioxidant activity, minerals. Moreover, there is an increase in shelf-life of developed bakery products.

Materials and methods

Raw material procurement and preparation

The tomato pomace used in this study was obtained by centrifuging home-made tomato puree at 4000 rpm at 4 °C for 15 min. Supernatant was in the form of tomato juice and retentate was tomato pomace that contained tomato skin, seed and pulp. The proximate analysis of tomato pomace was conducted following the standard method (AOAC 2005). Tomato pomace obtained had a protein content of 1.30 g/100 g, ash content of 2.2 g/100 g, fat content of 3.2 g/100 g, moisture content of 87 g/100 g and carbohydrate content of 6.3 g/100 g. Tomato pomace was then stored in HDPE containers at refrigerated temperature (4 °C) until further analysis and use. The high grade refined flour, sugar, salt, dried yeast, butter, baking powder and milk powder was also procured from local market of Mohali (Punjab), India for the development of bakery products.

Procedure of making bread and muffins

Tomato pomace was used to replace part of the refined flour in a standard bread recipe (Table S1) and muffin recipe (Table S2). Breads were supplemented with tomato pomace from 5 to 50% of flour weight and 35% of flour weight was found to be acceptable on sensory evaluation. Therefore, all analysis were performed on bread supplemented with 35% tomato pomace. Bread dough was prepared by mixing all ingredients for about 10–12 min with a whisker. Dough was fermented in bowls, covered with wet muslin cloth for 55 min at room temperature, punched and proofed at 30 °C for about 90 min to the optimum volume increase and then baked at 180–220 °C for 25 min and cooled at room temperature in laboratory conditions. Muffin were supplemented with tomato pomace from 5 to 50% of flour weight and 40% of flour weight was found to be acceptable on sensory evaluation. Liquid and dry ingredients for muffin like sugar, butter, milk, vanilla essence, tomato pomace, refined flour, baking powder were creamed in a mixer bowl by an electric blender for about 20 min, poured into mould of muffin paper and baked at 150–180 °C for 15–18 min until a light brown color was obtained.

Nutritional analysis of tomato pomace and bakery products

Protein was determined by the Kjeldahl method (AOAC 1995). Dietary fiber was determined with dietary fiber assay kit (Megazyme K-TDFR, Ireland) according to Mes-Tris method (AOAC 1995). Ascorbic acid was extracted and analyzed by reversed-phase HPLC (Nour et al. 2015). Lycopene determination was based on a spectrophotometric analysis (Nagata and Yamashita 1992). Antioxidant activity or DPPH free radical scavenging activity was measured using DPPH (2,2-diphenyl-1- picrylhydrazyl) assay with slight modification (Nour et al. 2015). Sodium (Na), calcium (Ca), magnesium (Mg), potassium (K), iron (Fe), were determined by ICP-MS (Cosmulescu et al. 2009).

Physical and sensory characterization of bread and muffin

The crumb color of bread and muffin was analyzed using Hunter Lab color measuring system (ColorFlex EZ, Hunter Associates Laboratory Inc., Reston, Virginia, USA). Approximately, 10 g sample was placed in a small glass bowl with a glass cover in order to provide uniform flat surface. Measured values were expressed as lightness (L*), red versus green (a*), yellow versus blue (b*) as described earlier (Chhanwal et al. 2015). Primary parameters like hardness, cohesiveness, and elasticity and secondary parameters like gumminess and chewiness were evaluated by texture profile analysis (TPA) test with texture analyzer TA-XT2i (TAHDI, Stable Microsystem, UK) using calibrated probe. The compression test was selected in texture analysis using a 5-kg load cell and sample was compressed to 45% of its original height. The strain required for 45% compression was recorded using the following conditions: pretest speed: 1.0 mm/s, test speed: 1.7 mm/s, post-test speed: 10 m/s, compression distance: 25% and trigger type: auto 5 g (AACC 2000). Sensory properties like color, flavor, texture and overall acceptability of all freshly baked products were evaluated using hedonic rating scale. Product samples were served to panelists to rate the acceptability on 1–9 point scale, ranging from extremely like (9) to dislike extremely (1) (Nour et al. 2015).

Shelf-life study of bread and muffin

Shelf-life study was conducted to observe the effect of addition of tomato pomace in bakery products. Study was conducted at two temperatures 10 and 25 °C. Moreover, the effect of combination of tomato pomace and half the amount of permitted chemical preservative sodium benzoate (170 ppm) was also studied. Indian standards (FSSAI/BIS) were followed to evaluate the shelf-life of bread and muffin which allows maximum 40% moisture content, 1.2% acidity of extracted fat, 10,000 cfu/g of total plate count and absence of yeast and mold growth.

Bread and muffin samples were prepared by mashing and mixing in peptone water. Samples were then spread plated on nutrient agar (NA) and potato dextrose agar (PDA) for the growth of bacterial and fungi count, respectively (APHA 2001). The moisture level was measured by hot air oven drying method (AOAC 2005). Acidity of extracted fat was measured by mixing with 50 ml of benzene alcohol phenolphthalein reagent and titrated with 0.1 N sodium hydroxide until pink color (Handa et al. 2012).

Statistical analysis

The data obtained were expressed as average of replicate ± standard deviation and was statistically analyzed by SPSS (version 22.0.0.0) to attain the reproducible results.

Result and Discussion

Nutritional content of raw tomato pomace

Tomato by-products used in this study recorded vitamin C content of 17.68 ± 0.24 mg/100 g (Table 1). In one of the earlier study, tomato pomace has been reported for vitamin C of 11.18 mg/100 g (Nour et al. 2015). Tomato by-product sample or pomace was found to possess antioxidant activity of 70.3 ± 0.25% (Table 1). High antioxidant activity of tomato pomace could be due to higher levels of vitamin C and polyphenol content. Moreover, phenolic compounds or natural antioxidants tend to accumulate in the dermal tissues of plant body because of their protective role against ultraviolet radiations and as a defense mechanism against pathogens and predators (Nour et al. 2015; Toor and Savage 2005).

Table 1.

Nutritional composition of raw tomato pomace and tomato pomace incorporated bread and muffin

| Parameter | Raw tomato pomace | Tomato pomace based bread | Control bread | Tomato pomace based muffin | Control muffin |

|---|---|---|---|---|---|

| Moisture content (g/100 g) | 87 ± 3.57 | 34 ± 2.11a | 33.2 ± 1.94b | 35.9 ± 0.221 | 32 ± 0.322 |

| Protein (g/100 g) | 1.30 ± 0.05 | 7.52 ± 0.03a | 7.22 ± 0.05b | 4.08 ± 0.121 | 3.5 ± 0.142 |

| Dietary fiber (g/100 g) | 3.75 ± 0.18 | 4.05 ± 0.12a | 2.00 ± 0.11b | 3.52 ± 0.151 | 2.99 ± 0.122 |

| Vitamin C (mg/100 g) | 17.68 ± 0.24 | 7.95 ± 0.16a | 1.23 ± 0.19b | 5.51 ± 0.111 | 1.12 ± 0.172 |

| Antioxidant (%) | 70.30 ± 0.25 | 48.70 ± 0.22a | 11.20 ± 0.31b | 45.30 ± 0.331 | 9.30 ± 0.252 |

| Lycopene (mg/100 g) | 12.00 ± 0.02 | 0.45 ± 0.06a | ND | 0.40 ± 0.081 | ND |

| Calcium (mg/100 g) | 14.64 ± 0.03 | 27.45 ± 0.12a | 22.39 ± 0. 13b | 14.19 ± 0.141 | 11.30 ± 0.112 |

| Iron (mg/100 g) | 2.92 ± 0.14 | 2.90 ± 0.11a | 2.50 ± 0.15b | 3.48 ± 0.161 | 1.49 ± 0.152 |

| Sodium (mg/100 g) | 21.03 ± 0.12 | 615.84 ± 0.13b | 647.94 ± 0.10a | 461.40 ± 0.121 | 381.37 ± 0.112 |

| Magnesium (mg/100 g) | 28.13 ± 0.13 | 44.93 ± 0.17a | 37.18 ± 0.18b | 28.62 ± 0.141 | 25.50 ± 0.142 |

| Potassium (mg/100 g) | 268.69 ± 0.14 | 197. 61 ± 0.10a | 133.74 ± 0.13b | 100.39 ± 0.141 | 71.53 ± 0.172 |

Values are presented as mean ± standard deviation (n = 3)

Values with different alphabetical superscripts differ significantly in a row at p < 0.05 for each test

Values with different numeric superscripts differ significantly in a row at p < 0.05 for each test

Tomato pomace was observed to contain protein content of 1.3 ± 0.05 g/100 g and dietary fiber content of 3.75 ± 0.18 g/100 g (Table 1). Tomato by-products have been documented as good source of dietary fiber and protein (García Herrera et al. 2010; Mironeasa et al. 2016). The lycopene content of tomato pomace was found 12 ± 0.02 mg/100 g (Table 1). Lycopene content of 17.4 mg/100 g tomato pomace has been reported by Nour et al. (2015). This might be due to the differences in tomato variety, cultivation conditions and their processing. Among mineral content, potassium content was found to be the highest (268.69 ± 0.14 mg/100 g), followed by magnesium (28.13 ± 0.13 mg/100 g), sodium (21.03 ± 0.12 mg/100 g), calcium (14.64 ± 0.03 mg/100 g) and iron (2.92 ± 0.14 mg/100 g) (Table 1). Similar minerals content has been reported earlier for tomato pomace (Nour et al. 2015). Hence, the tomato pomace or tomato processing by-products are rich source of vitamin C, antioxidants and minerals content and therefore used for valorization in bakery food products.

Effect of tomato by-product addition on nutritional composition of bread and muffin

Fresh tomato pomace was incorporated into breads and muffins to give fruity taste and appealing color. On sensory evaluation, fresh tomato pomace incorporated breads and muffins were liked most than dry tomato pomace incorporated one. Therefore, fresh tomato pomace incorporated breads and muffins were used for various analysis. Nutritional composition data of the control and tomato based bread and muffin are given in Table 1. The addition of tomato pomace was found to significantly increase (p < 0.05) the dietary fiber of bread and muffins. Incorporation of tomato pomace in bread and muffin led to higher dietary fiber of 4.05 and 3.52 g/100 g respectively in comparison to 2 and 2.99 g/100 g in their respective controls. Tomato pomace comprised of tomato skin, seed, and pulp contains good amount of dietary fiber which might be the reason for increase in dietary fiber content in bread and muffin (García Herrera et al. 2010). Moreover, the increased dietary fiber content in crackers has been reported by the supplementation of tomato pomace (Isik and Topkaya 2016). As dietary fiber physically disrupts the gluten and starch matrix (Nour et al. 2015), addition of dietary fiber rich tomato pomace was found to reduce the volume of bread and muffins and that imparted more health value.

Vitamin C content of bread and muffins was increased from 1.23 to 7.95 mg/100 g and 5.51 to 1.12 mg/100 g respectively with the addition of tomato byproducts. High levels of vitamin C in tomatoes or tomato pomace has been reported earlier as well (Bhat and Ahsan 2015; Strati and Oreopoulou 2011; Toor and Savage 2005). Antioxidant activity of bread and muffin was also found to be increased (48.7 and 45.3%) in comparison to their controls (11.2 and 9.3%), respectively. The reason for increased antioxidant activity could be due to higher phenolic content and antioxidant activity of tomato pomace than wheat flour. Moreover, tomato skin is rich source of lycopene and other carotenoids like β-carotene and vitamin C which might have imparted to the higher levels of antioxidant activity in bread and muffin (Kamiloglu et al. 2013, 2014). The antioxidant activity of tomato peel extract in petroleum ether, methanol, chloroform and ethyl acetate extracts has been reported higher to the extent of 97.32, 97.07, 96.30 and 86.4%, respectively (Elbadrawy and Sello 2016). In present study, lycopene content was also observed to be 0.45 mg/100 g in bread and 0.40 mg/100 g in muffin, while it was absent in control products. Tomato pomace used in this study contained as high as 12 mg lycopene/100 g pomace. Moreover, high content of lycopene to the extent of 17.41 mg/100 g has also been reported earlier in tomato pomace (Nour et al. 2015).

Among minerals, potassium content was found higher (197.61 and 100.39 mg/100 g, respectively), followed by magnesium (44.93 and 28.62 mg/100 g, respectively), calcium (27.45 and 14.19 mg/100 g, respectively) and iron (2.9 and 3.48 mg/100 g, respectively) in bread and muffins as compared to control products. Interestingly, tomato incorporated bread was found to be lower on sodium content compared to their controls. Lower sodium content could be due to fermentation or baking process upon tomato byproducts incorporation. Wheat bread supplemented with oyster mushroom has been reported for increased mineral content (Ndung’u et al. 2015).

Effect of tomato by-product addition on physical and sensory character of bread and muffin

Color (L*, a*, b*)

The results of Hunter Lab color value of bread and muffins are shown in Table 2. In this, L* stands for lightness, a* stand for red and green color, b* stands for yellow and blue color. Addition of tomato pomace was observed for decreasing effect on L* color value and increasing effect on a* and b* color values. The L* value of control bread and muffin was 72.41 and 82.26, respectively and those of tomato based bread and muffin was 58.81 and 60.39, respectively, indicating that lightness was decreased with the reduction in proportion of wheat flour. Therefore, bread and muffin were observed to be darker with increase in addition of tomato pomace level. The a* value representing redness was found to be 2.11 and 1.95 for control bread and muffin respectively. The higher a* values of tomato based bread (23.28) and muffins (21.96), indicating their more reddish color. The b* value representing yellowness was found to be 15.3 and 29.53 for control bread and muffin. The more yellow color of tomato based bread and muffins was due to their higher b* value of 44.76 and 35.53 respectively. Bhat and Ahsan (2015) have also reported darker, more red and yellow color of tomato pomace powder incorporated cookies. Similarly, with increasing amount of tomato pomace powder incorporation in crackers, their color become darker, more red and yellow (Isik and Topkaya 2016). Singh et al. (2003) have also reported darker and more redness and yellowness colored cookies made with corn and potato flour.

Table 2.

Color and Textural characteristics of bread and muffin

| Parameters | Control bread | Tomato bread | Control muffin | Tomato muffin |

|---|---|---|---|---|

| Color parameter | ||||

| L* | 72.41 ± 2.25a | 58.18 ± 2.11b | 82.26 ± 1.211 | 60.39 ± 1.322 |

| a* | 2.11 ± 0.11b | 23.28 ± 1.12a | 1.95 ± 0.222 | 21.96 ± 1.121 |

| b* | 15.30 ± 1.12b | 44.76 ± 1.22a | 29.53 ± 1.512 | 35.53 ± 2.691 |

| TPA parameters | ||||

| Hardness (N) | 3.68 ± 0.45a | 0.011 ± 0.02b | 70.82 ± 0.341 | 47.14 ± 0.632 |

| Adhesiveness (N s) | 0.23 ± 0.03a | 0.27 ± 0.04a | 0.40 ± 0.032 | 0.59 ± 0.071 |

| Springiness | 0.87 ± 0.05b | 0.99 ± 0.10a | 0.98 ± 0.112 | 1.62 ± 0.721 |

| Cohesiveness | 0.72 ± 0.02b | 0.77 ± 0.15a | 0.71 ± 0.062 | 0.99 ± 0.051 |

| Gumminess | 1.17 ± 0.30b | 1.34 ± 0.03a | 50.79 ± 0.111 | 46.88 ± 0.442 |

| Chewiness | 4.58 ± 0.52b | 5.32 ± 0.44a | 50.03 ± 0.432 | 96.49 ± 0.771 |

Values are presented as mean ± standard deviation (n = 3)

Values with different alphabetical superscripts differ significantly in a row at p < 0.05 for each test

Values with different numeric superscripts differ significantly in a row at p < 0.05 for each test

Texture

The texture of bread and muffins was analyzed in terms of hardness, adhesiveness, springiness, cohesiveness, gumminess and chewiness (Table 2). Tomato pomace addition was found to increase the crumb firmness leading to lower hardness value in both tomato based bread and muffin. This may be attributed to the presence of good amount of hydrocolloid in tomato pomace which can increase the water absorption of flour and made it softer (Majzoobi et al. 2011). Also, tomato pomace incorporation in bread and muffin was observed to increase the value of chewiness, cohesiveness, springiness and other parameters. Higher levels of fiber in tomato pomace usually leads to provide firm texture to the products (Wang et al. 2002). Moreover, hydrocolloid nature of tomato pomace might inhibit association between starch chains and reduce the starch retrogradation (Majzoobi et al. 2011) and therefore, retarded hardness and promoted springiness and chewiness in the prepared bread and muffins.

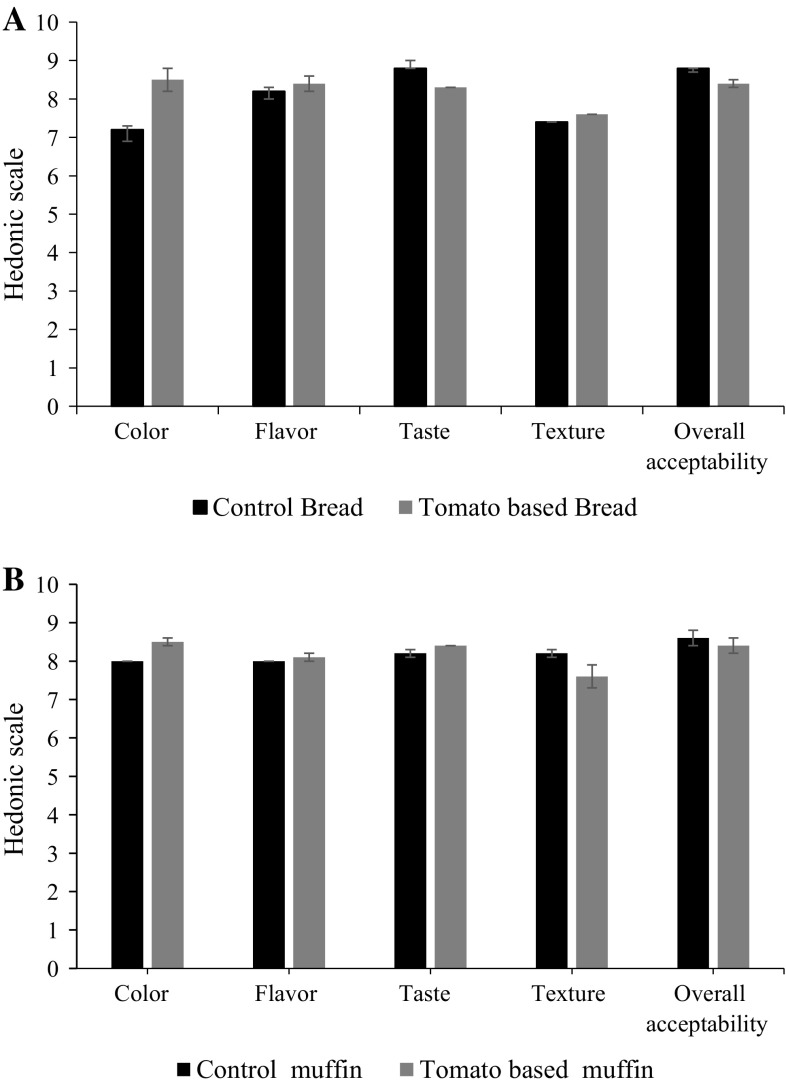

Sensory

Sensory acceptability scores was recorded for various attributes of tomato based bread (Fig. 1a) and muffin (Fig. 1b) in comparison to their respective controls. All the samples of bread and muffins were sensory acceptable. However, panelist preferred control bakery products which registered the highest score for overall acceptability. Scores obtained from sensory panelist indicated that tomato based bread and muffins were more appealing in terms of color. Moreover, texture of bread and muffin was slightly less acceptable than control samples. Furthermore, taste and flavor were more acceptable in case of muffins but slightly less in case of bread as compared to their respective controls. Similar trend for sensory has been observed earlier in tomato based crackers and cookies (Bhat and Ahsan 2015; Nour et al. 2015).

Fig. 1.

Sensory evaluation of tomato based bread (a) and muffin (b)

Effect of tomato by-product addition on shelf-life parameters of bread and muffin

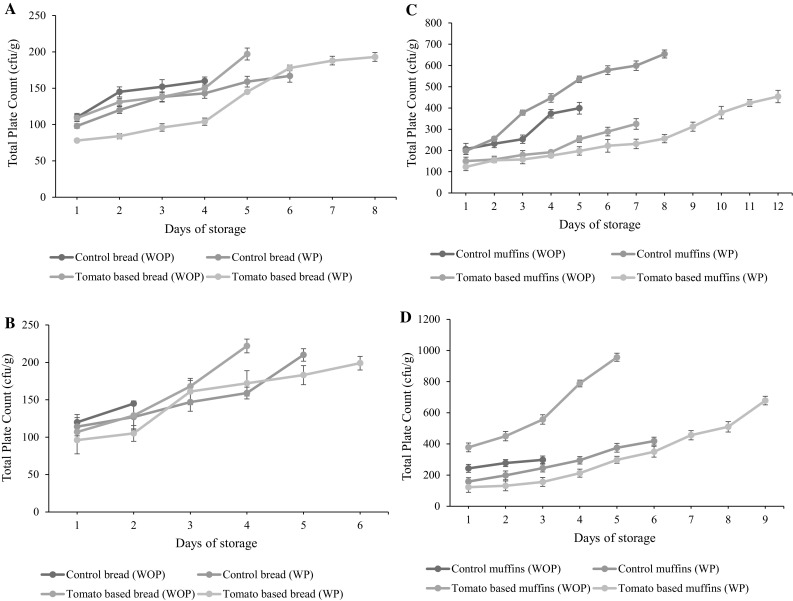

Microbiological stability

Addition of tomato pomace in bread and muffin was found to increase their shelf-life (Fig. 2). According to Indian standards, maximum 40% moisture content, 1.2% acidity of extracted fat, 10,000 cfu/g of total plate count and absence of yeast and mold growth are considered to be shelf life determining factors. Control bread with preservatives were observed to have a shelf life of 6 days at 10 °C (Fig. 2a) and 5 days at 25 °C (Fig. 2b). The shelf life of tomato based bread with preservative was found to be increased to 8 days at 10 °C (Fig. 2a) and 6 days at 25 °C (Fig. 2b). Tomato based bread without preservative have possessed shelf life of 5 days at 10 °C (Fig. 2a) and 4 days at 25 °C (Fig. 2b) in comparison to 4 days at 10 °C and 2 days at 25 °C for control. Similarly, tomato based muffins were observed to have more shelf life. Tomato based muffin with preservative were observed for shelf life of 12 days at 10 °C (Fig. 2c) and 9 days at 25 °C (Fig. 2d) in comparison to 8 days at 10 °C (Fig. 2c) and 6 days at 25 °C (Fig. 2d) for control muffin with preservative. Tomato based muffin without preservative still have higher shelf life of 7 days at 10 °C (Fig. 2c) and 5 days at 25 °C (Fig. 2d) in comparison to 5 days at 10 °C and 3 days at 25 °C for control muffin without preservative. The enhanced shelf-life of tomato based bread and muffin might be due to antioxidant compounds like lycopene and vitamin C that provided protection against microbial growth. Addition of raisins at 12% on flour basis has been reported to inhibit the growth of mold and increased the shelf-life of wheat bread by 1–3 days (Lagrange and Payne 1988). Moreover, tomato pomace powder has also been reported to delay the staling when stored at 25 °C (Majzoobi et al. 2011).

Fig. 2.

Total bacterial count in tomato based bread during storage at 10 °C (a) and 25 °C (b) with (WP) or without (WOP) preservative. Total bacterial count in tomato based muffin during storage at 10 °C (c) and 25 °C (d) with (WP) or without (WOP) preservative. Analysis was stopped after the mold growth in products

Chemical parameter stability

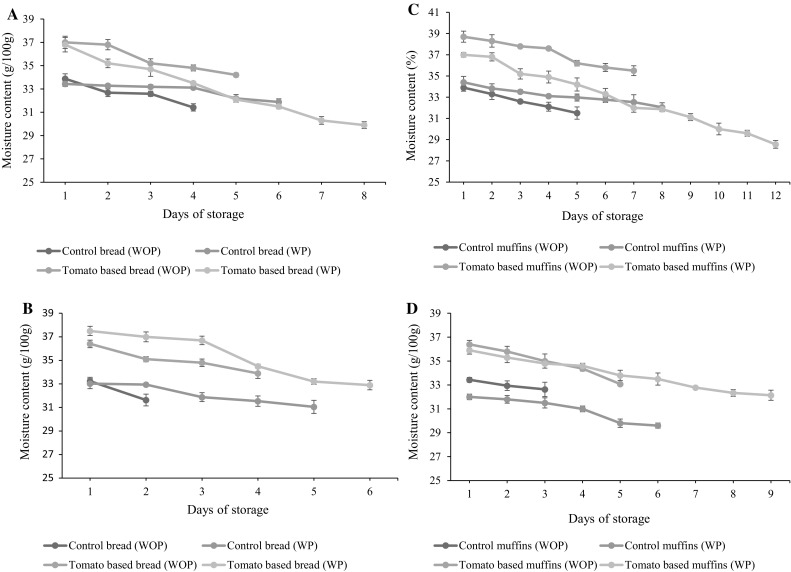

Moisture content

Tomato pomace addition in bread and muffin was observed to increase their moisture content that control bakery products (Fig. 3). It might be attributed due to greater water holding capacity of the tomato pomace than that of wheat flour (Nour et al. 2015). Moreover, tomato pomace might increase the water absorption of the flour due to presence of hydrocolloidal properties which allows more water interaction through hydrogen bonding (Shalini and Laxmi 2007; Majzoobi et al. 2011). During shelf-life analysis, moisture content of bread at 10 °C (Fig. 3a) and 25 °C (Fig. 3b) and muffin at 10 °C (Fig. 3c) and 25 °C (Fig. 3d) was found to be slightly decreased during storage. Moreover, moisture content was in permissible limit (40%) till mold growth appeared.

Fig. 3.

Moisture content of tomato based bread during storage at 10 °C (a) and 25 °C (b) with (WP) or without (WOP) preservative. Moisture content of tomato based muffin during storage at 10 °C (c) and 25 °C (d) with (WP) or without (WOP) preservative

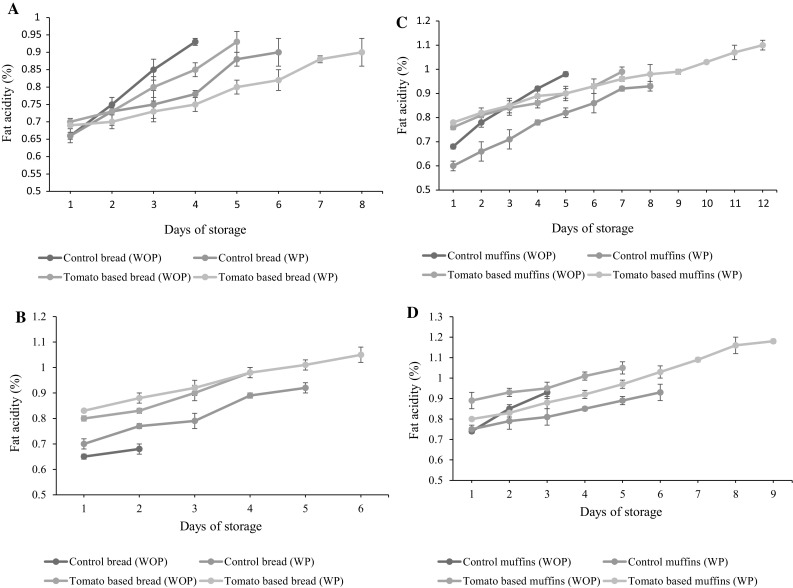

Acidity of extracted fat

Tomato pomace added bread at 10 °C (Fig. 4a) and 25 °C (Fig. 4b) and muffin at 10 °C (Fig. 4c) and 25 °C (Fig. 3d) were observed for higher acidity of fat as compared to control bakery products. It might be attributed to the higher levels of antioxidants of tomato pomace. Moreover, increase in acidity of fat content is associated with lengthening of storage period (Nagi et al. 2012). Acidity of extracted fat in bread and muffins was at permissible limits of 1.2% till mold growth appeared.

Fig. 4.

Acidity of extracted fat of tomato based bread during storage at 10 °C (a) and 25 °C (b) with (WP) or without (WOP) preservative. Acidity of extracted fat of tomato based muffin during storage at 10 °C (c) and 25 °C (d) with (WP) or without (WOP) preservative

Conclusion

Bread and muffin supplemented with tomato pomace show enhanced nutritional properties like dietary fiber, vitamin C, antioxidant activity and minerals. Moreover, incorporation of tomato pomace led to acceptable color and sensory properties and also had softer crumb texture as compared to control bakery products. Furthermore, tomato pomace incorporation in bread and muffins has been found to enhance their shelf-life in comparison of control bakery products with or without preservatives. Hence, by-products of the tomato processing industry could be a rich source of antioxidants, minerals, and dietary fiber for human health importance. Bread and muffin supplemented with tomato by-product showed good physicochemical characteristics and an adequate sensory profile. Moreover, drying of tomato pomace powder could also be a useful step for addition in bakery products. Findings of this study would help in promoting the use of different by-products of the fruits and vegetables processing industries, rich in various bioactive compounds, as food ingredients.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Acknowledgements

CEO, CIAB is duly acknowledged for his continuous support and encouragement. The authors are highly thankful to Department of Biotechnology (DBT) for financial support (BT/PR12546/PFN/20/976/2014). This work has been filed as a patent with Application No. 201711042760.

Compliance with ethical standards

Conflict of interest

Authors declare that they have no conflict of interest.

Footnotes

Electronic supplementary material

The online version of this article (10.1007/s13197-018-3176-0) contains supplementary material, which is available to authorized users.

References

- AACC . Approved methods of the American Association of cereal chemists. 9. St. Paul: American Association of Cereal Chemists; 2000. [Google Scholar]

- Adalid AM, Roselló S, Nuez F. Evaluation and selection of tomato accessions (Solanum Lycopersicon) for content of lycopene, β-carotene and ascorbic acid. J Food Comp Anal. 2010;23:613–618. doi: 10.1016/j.jfca.2010.03.001. [DOI] [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Evaluation of snack foods from barley-tomato pomace blends by extrusion processing. J Food Eng. 2008;84:231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Alves AB, Bragagnolo N, da Silva MG, Skibsted LH, Orlien V. Antioxidant protection of high-pressure processed minced chicken meat by industrial tomato products. Food Bioprod Proc. 2012;90:499–505. doi: 10.1016/j.fbp.2011.10.004. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. Washington: Association of Official Analytical Chemists; 1995. [Google Scholar]

- AOAC . Official methods of analysis. Washington: Association of Official Analytical Chemists; 2005. [Google Scholar]

- APHA . Compadium of methods for the microbiological examination of foods. 4. Washington: American Public Health Association; 2001. [Google Scholar]

- Bhat MA, Ahsan H. Physico-chemical characteristics of cookies prepared with tomato pomace powder. J Food Proc Tech. 2015;7:543. [Google Scholar]

- Chhanwal N, Ezhilarasi PN, Indrani D, Anandharamakrishnan C. Influence of electrical and hybrid heating on bread quality during baking. J Food Sci Technol. 2015;52(7):4467–4474. doi: 10.1007/s13197-014-1478-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Cosmulescu S, Baciu A, Achim G, Botu M, Trandafir I. Mineral composition of fruits in different walnut (Juglans regia L.) cultivars. Not Bot Hort Agrobot. 2009;37(2):156–160. [Google Scholar]

- Del Valle M, Cámara M, Torija ME. Chemical characterization of tomato pomace. J Sci Food Agri. 2006;86:1232–1236. doi: 10.1002/jsfa.2474. [DOI] [Google Scholar]

- Elbadrawy E, Sello A. Evaluation of nutritional value and antioxidant activity of tomato peel extracts. Arab J Chem. 2016;9:S1010–S1018. doi: 10.1016/j.arabjc.2011.11.011. [DOI] [Google Scholar]

- García Herrera P, Sánchez-Mata MC, Cámara M. Nutritional characterization of tomato fiber as a useful ingredient for food industry. Innov Food Sci Emerg Tech. 2010;11:707–711. doi: 10.1016/j.ifset.2010.07.005. [DOI] [Google Scholar]

- García ML, Calvo MM, Selgas MD. Beef hamburgers enriched with lycopene using dry tomato peel as ingredient. Meat Sci. 2009;83:45–49. doi: 10.1016/j.meatsci.2009.03.009. [DOI] [PubMed] [Google Scholar]

- Handa C, Goomer S, Siddhu A. Physicochemical properties and sensory evaluation of fructoligosaccharide enriched cookies. J Food Sci Techn. 2012;2:192–199. doi: 10.1007/s13197-011-0277-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Isik F, Topkaya C. Effects of tomato pomace supplementation on chemical and nutritional properties of crackers. Ital J Food Sci. 2016;28:525–535. [Google Scholar]

- Kamiloglu S, Boyacioglu D, Capanoglu E. The effect of food processing on bioavailability of tomato antioxidants. J Berry Res. 2013;3:65. [Google Scholar]

- Kamiloglu S, Demirci M, Selen S, Toydemir G, Boyacioglu D, Capanoglu E. Home processing of tomatoes (Solanum lycopersicum): effects on in vitro bioaccessibility of total lycopene, phenolics, flavonoids, and antioxidant capacity. J Sci Food Agri. 2014;94:2225. doi: 10.1002/jsfa.6546. [DOI] [PubMed] [Google Scholar]

- Knoblich M, Anderson B, Latshaw D. Analyses of tomato peel and seed byproducts and their use as a source of carotenoids. J Sci Food Agri. 2005;85:1166. doi: 10.1002/jsfa.2091. [DOI] [Google Scholar]

- Lagrange V, Payne TJ. Shelf life extension of food products containing raisins & raisin products. Cereal Foods World. 1988;33(2):211–214. [Google Scholar]

- Majzoobi M, Ghavi FS, Farahnaky A, Jamalian J, Mesbahi G. Effect of tomato pomace powder on the physicochemical properties of flat bread (barbari bread) J Food Process Preserv. 2011;35:247–256. doi: 10.1111/j.1745-4549.2009.00447.x. [DOI] [Google Scholar]

- Martínez-Hernández GB, Boluda-Aguilar M, Taboada-Rodríguez A, Soto-Jover S, Marín-Iniesta F, López-Gómez A. Processing, packaging, and storage of tomato products: influence on the lycopene content. Food Eng Rev. 2016;8(1):52–75. doi: 10.1007/s12393-015-9113-3. [DOI] [Google Scholar]

- Mironeasa S, Codină GG, Oroian MA. Bread quality characteristics as influenced by the addition of tomato seed flour. Bull Univ Agric Sci Vet Med. 2016;73(2):77–84. [Google Scholar]

- Nagata M, Yamashita I. Simple method for simultaneous determination of chlorophyll and carotenoids in tomato fruit. The Jap Soc Food Sci Tech. 1992;39:925–928. doi: 10.3136/nskkk1962.39.925. [DOI] [Google Scholar]

- Nagi HPS, Kaur J, Dar BN, Sharma S. Effect of storage period and packaging on the shelf life of cereal bran incorporated biscuits. Am J Food Tech. 2012;7:301–310. doi: 10.3923/ajft.2012.301.310. [DOI] [Google Scholar]

- Ndung’u SW, Otieno CA, Onyango C, Musieba F. Nutritional composition, physical qualities and sensory evaluation of wheat bread supplemented with oyster mushroom. Am J Food Tech. 2015;10:279–288. doi: 10.3923/ajft.2015.279.288. [DOI] [Google Scholar]

- Nour V, Ionica ME, Trandafir I. Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste. J Food Sci Tech. 2015;52(12):8260–8267. doi: 10.1007/s13197-015-1934-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pinela J, Barros L, Carvalho AM, Ferreira IC. Nutritional composition and antioxidant activity of four tomato (Lycopersicon esculentum L.) farmer’ varieties in Northeastern Portugal homegardens. Food Chem Toxic. 2012;50:829–834. doi: 10.1016/j.fct.2011.11.045. [DOI] [PubMed] [Google Scholar]

- Quail K. Arabic bread production. St. Paul: American Association of Cereal Chemists Inc; 2004. pp. 10–50. [Google Scholar]

- Rahmatnejad E, Bojarpour M, Mirzadeh Kh, Chaji M, Mohammadabadi T. The effects of different levels of dried tomato pomace on broilers chicken hematological indices. J Anim Vet Adv. 2009;8(10):1989. [Google Scholar]

- Rao AV, Agarwal S. Role of lycopene as antioxidant carotenoid in the prevention of chronic diseases: a review. Nut Res. 1999;19:305–323. doi: 10.1016/S0271-5317(98)00193-6. [DOI] [Google Scholar]

- Shalini KJ, Laxmi A. Influence of additives on rheological characteristics of whole-wheat dough and quality of Chapatti (Indian unleavened flat bread). Part I. Hydrocolloids. Food Hydrocoll. 2007;21:110–117. doi: 10.1016/j.foodhyd.2006.03.002. [DOI] [Google Scholar]

- Singh J, Singh N, Sharma TR, Saxena SK. Physicochemical, rheological and cookie making properties of corn and potato flours. Food Chem. 2003;83:387–393. doi: 10.1016/S0308-8146(03)00100-6. [DOI] [Google Scholar]

- Sogi DS, Arora MS, Garg SK, Bawa AS. Fractionation and electrophoresis of tomato waste seed proteins. Food Chem. 2002;76:449. doi: 10.1016/S0308-8146(01)00304-1. [DOI] [Google Scholar]

- Strati IF, Oreopoulou V. Effect of extraction parameters on the carotenoid recovery from tomato waste. Int J Food Sci Tech. 2011;46:23. doi: 10.1111/j.1365-2621.2010.02496.x. [DOI] [Google Scholar]

- Takachi R, Manami I, Junko I, Norie K, Motoki I, Sasazuki S, Iso H, Tsubono Y, Tsugane S, JPHC Study Group Fruit and vegetable intake and risk of total cancer and cardiovascular disease: Japan public health center-based prospective study. Am J Epidem. 2008;167:59–70. doi: 10.1093/aje/kwm263. [DOI] [PubMed] [Google Scholar]

- Toor RK, Savage GP. Antioxidant activity in different fractions of tomatoes. Food Res Int. 2005;38:487–494. doi: 10.1016/j.foodres.2004.10.016. [DOI] [Google Scholar]

- Wang J, Rosell CM, De Barber Benedito C. Effect of the addition of different fibers on wheat dough performance and bread quality. Food Chem. 2002;79:221–226. doi: 10.1016/S0308-8146(02)00135-8. [DOI] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.