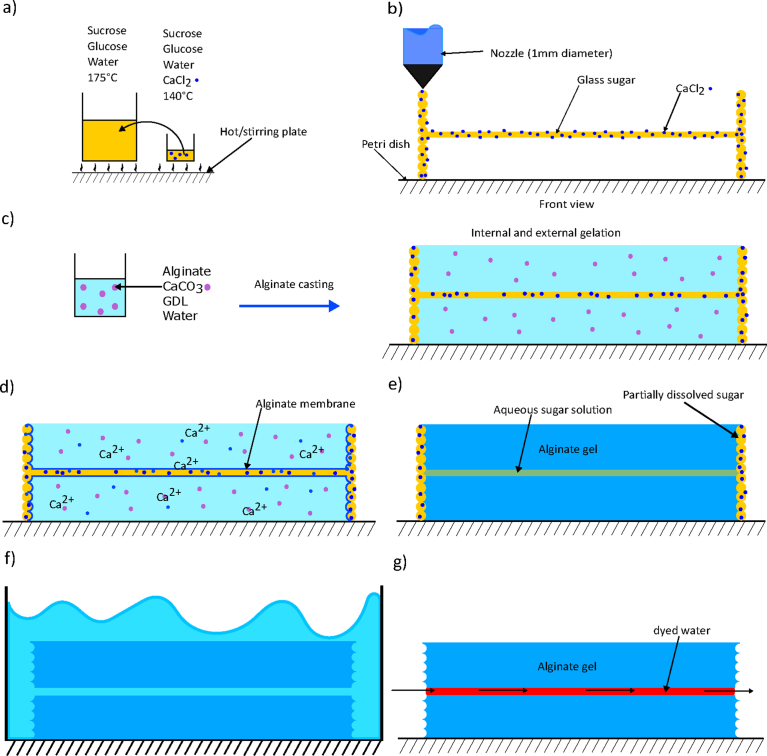

Fig. 1.

Schematic procedure. a) Sugar recipe preparation, b) 3D printing of the sugar glass construct loaded with calcium chloride, c) Preparation and casting of the alginate mixture, containing CaCO3 and GDL, (t = 0), d) Immediately after casting the alginate mixture, formation of a membrane at the sugar/ALG interface due to the release of the Ca2+ ions from the CaCl2 contained in the fugitive ink, (t = 0+), e) Completed internal gelation of alginate, (t = 600 s), f) Dissolution of the remaining sugar glass template in a demineralized water bath, g) Perfusion of the alginate gel with red food dye.