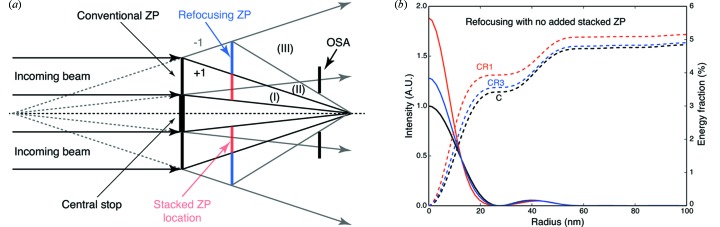

Figure 11.

Refocusing zone plates can recapture some of the  = −1-order focus light from a conventional zone plate. This is shown schematically in (a), where one can produce a combined optic with a stacked zone plate in the inner diameter and a refocusing zone plate operating in either

= −1-order focus light from a conventional zone plate. This is shown schematically in (a), where one can produce a combined optic with a stacked zone plate in the inner diameter and a refocusing zone plate operating in either  = 1 or first diffraction order, or

= 1 or first diffraction order, or  = 3 or third diffraction order. The effect on the focus profile and integrated energy as a function of radius is shown in (b), for the cases of a conventional zone plate alone (case C), or with the addition of a refocusing zone plate operating in first diffraction order (case CR1), or with a refocusing zone plate operating in third diffraction order (case CR3). Both refocusing zone plates offer an increase in focal efficiency, with the CR1 case also offering an improvement in spatial resolution. However, in the CR1 case the refocusing zone plate must have finer zone width

= 3 or third diffraction order. The effect on the focus profile and integrated energy as a function of radius is shown in (b), for the cases of a conventional zone plate alone (case C), or with the addition of a refocusing zone plate operating in first diffraction order (case CR1), or with a refocusing zone plate operating in third diffraction order (case CR3). Both refocusing zone plates offer an increase in focal efficiency, with the CR1 case also offering an improvement in spatial resolution. However, in the CR1 case the refocusing zone plate must have finer zone width  than the conventional zone plate, and usually the conventional zone plate is fabricated out to the limits of what can be achieved in nanolithography; in the CR3 case, the finest zone width

than the conventional zone plate, and usually the conventional zone plate is fabricated out to the limits of what can be achieved in nanolithography; in the CR3 case, the finest zone width  is the same for the conventional (C) and third-order refocusing (R3) zone plates. The parameters for the zone plates used for the calculation of focal intensities (b) are given in Table 2 ▸.

is the same for the conventional (C) and third-order refocusing (R3) zone plates. The parameters for the zone plates used for the calculation of focal intensities (b) are given in Table 2 ▸.