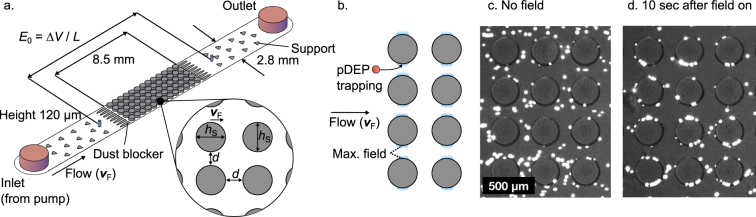

Figure 1.

Scheme of the microfluidic system that serves as model porous medium (a). The microchannels have a height of 120 μm and a width of 2.8 mm. An array of insulating posts with cross-sectional diameter hS is located in the center of the channel. They are placed a distance of d apart. The entire array has a length of 8 mm. The fluid velocity vector results from the pressure-driven volume flow Q through the channel. Elongated dust blockers are located in front and behind of the post array. The electric field E0 = ΔV/L across the array is generated by applying a voltage ΔV using two platinum electrodes (blue). Fluid inlet and outlet is realized using PTFE tubing (red) and fluid transport is achieved using a syringe pump. Triangular support structures are located in the channel to prevent it from collapsing. Principle of positive DEP (pDEP) particle trapping in the post array (b). The electric field is disturbed by the posts so that it shows maxima at the openings in each line of posts at the points that are on a line perpendicular to the flow and applied field direction. Particles experiencing positive DEP will become immobilized at these field maxima that act as particle traps. Snapshot of a microchannel with polystyrene model particles without (c) and ten seconds after application of the electric field (d); see also Supplementary movie S1.