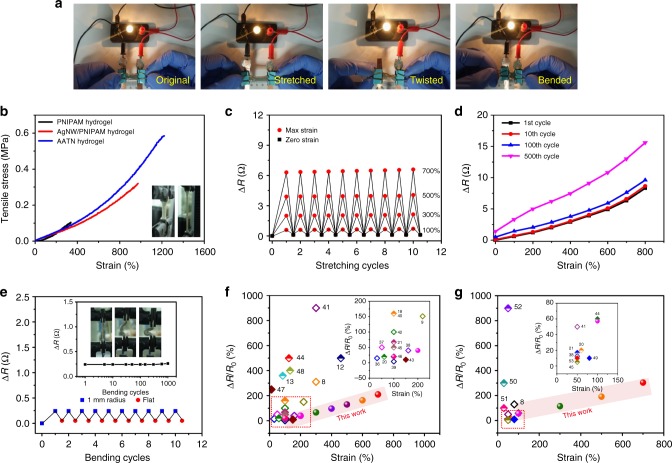

Fig. 3.

Mechanical and electromechanical performances. a Photographs demonstrating good electrical conductivity of AATN hydrogel when stretched, twisted and bended. b Tensile stress–strain curves of PNIPAM hydrogel (black line), AgNW/PNIPAM hydrogel (red line), and AATN hydrogel (blue line). The inset showing AATN hydrogel when stretched. c Variation of electrical resistance (ΔR) of AATN hydrogel during 10 stretching-releasing cycles with the fixed strains of 100, 300, 500, and 700%, respectively. d ΔR values of AATN hydrogel during 1st, 10th, 100th, and 500th cycle with a continuous stretching up to a strain of 800%. e ΔR values of AATN hydrogel during the bending-releasing cycles with a small bending radius of 1 mm. The inset showing the hydrogel during bending process and ΔR values during 1000 cycles. f Ashby chart plotting normalized resistance change (ΔR/R0) vs. tensile strain of AATN hydrogel and the reported stretchable conductors. The inset showing enlarged view of the rectangular area. Numbers stand for relevant references. (Hollow diamond: CNT-based stretchable conductor; solid diamond: graphene-based conductor; semi-hollow diamond: metal nanowire-based conductor; and solid sphere: AATN hydrogel). g Ashby chart plotting ΔR/R0 vs. tensile strain of AATN hydrogel and the reported stretchable conductors with 100 stretching cycles. The insert showing enlarged view of the rectangular area. Numbers stand for relevant references. (Hollow diamond: CNT-based conductor; semi-hollow diamond: metal nanowire-based conductor; solid diamond: other conductor; and solid sphere: AATN hydrogel)