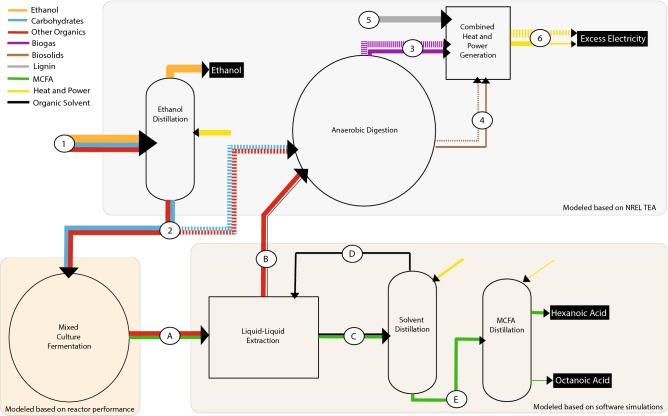

Fig. 1.

Energy balance through a proposed lignocellulosic biorefinery that simultaneously produces ethanol, electricity, and MCFAs. For this study, we modeled anaerobic digestion and combined heat and power generation using criteria used in a 2011 technoeconomic analysis performed by NREL. We modeled a MCFA-producing mixed culture fermentation process based on productivities observed in this study. Commercially available software was utilized for the modeling of downstream processes to extract and separate hexanoic and octanoic acids. In the proposed biorefinery, a portion of organic matter remaining in stillage is converted to MCFAs, which can be recovered via liquid–liquid extraction and distillation. Remaining organic matter undergoes anaerobic digestion to produce biogas that is combusted, along with lignin and biosolids, to produce electricity. Dashed lines represent current process flows for converting organic materials in stillage directly to biogas. Solid lines represent proposed processes for producing MCFA as a co-product. Line weights are proportional to approximate energy content represented as chemical oxygen demand (COD) for liquid and gas streams and as megawatts (MW) for heat and power. Process streams include (1) fermented hydrolysate; (2) stillage; (3) biogas; (4) biosolids; (5) lignin; (6) heat and power; (A) fermented stillage; (B) aqueous phase; (C) organic phase; (D) organic solvent; and (E) MCFAs