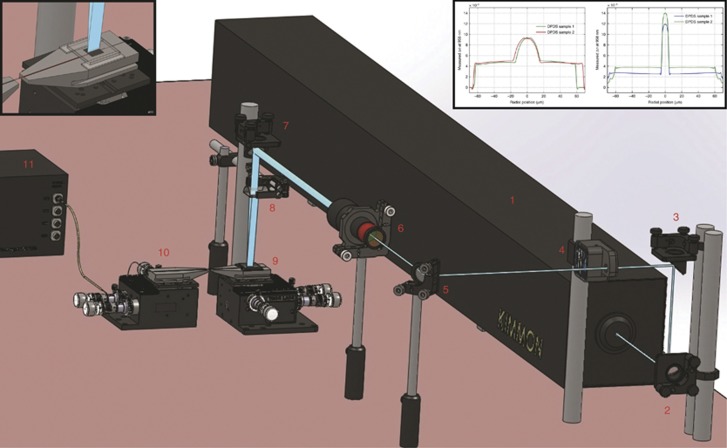

Figure 1.

Polymer optical FBG fabrication setup using a static beam. The setup used 4 mirrors (2, 3, 5 and 7) to guide the laser beam from (1) to (9). The beam shutter (4) is inserted in the optical path after the second mirror (3), and the 10 × beam expander (6) was placed after the third mirror (5) to expand the beam. The plano-convex cylindrical lens (8) focuses the beam onto the fibre. The FBGs' spectra was recorded with an FBG interrogator (11) via an angled-cleaved single mode fibre (10). The upper left corner shows the POF with the phase mask placed on top of the V-groove. The measured refractive index profiles at 958 nm of two samples of DPDS core-doped POFs fabricated using the Teflon string method (left) and DPDS core-doped fibres fabricated using the ‘pull-through’ method (right) are shown in the upper right corner.