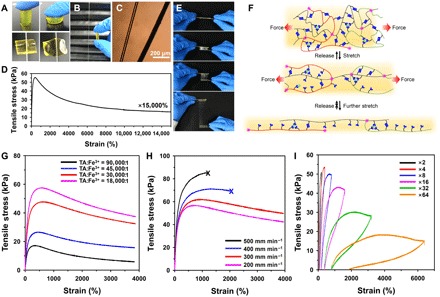

Fig. 2. Mechanical properties of poly(TA-DIB-Fe) copolymer.

(A) A free-standing copolymer can be pressed without fragmentation and cannot be cut easily with a knife. (B) A rod-like copolymer can be stretched into a thin filament. (C) Optical microscopy image of a stretched copolymer filament (left) with a human hair (right) as a reference. (D) Stress-strain curve of the resulting network [TA-to-iron(III) molar ratio of 18,000:1] for a strain of 15,000%. (E) Photographs of the stretchable viscous copolymer adhered between the two glass slices. The copolymer was first preheated to the viscous state and then deposited onto glass surfaces. (F) Proposed energy dissipation mechanism for ultrahigh stretchability. (G) Stress-strain curves of the copolymer with different iron(III) concentrations. (H) Stress-strain curves of the copolymer at varied strain rates [TA-to-iron(III) molar ratio of 18,000:1]. (I) Sequential loading-unloading stress-strain curves without rest internals [TA-to-iron(III) molar ratio of 18,000:1]. The successful stretching without breaking proves the resistance of the copolymer to fatigue.