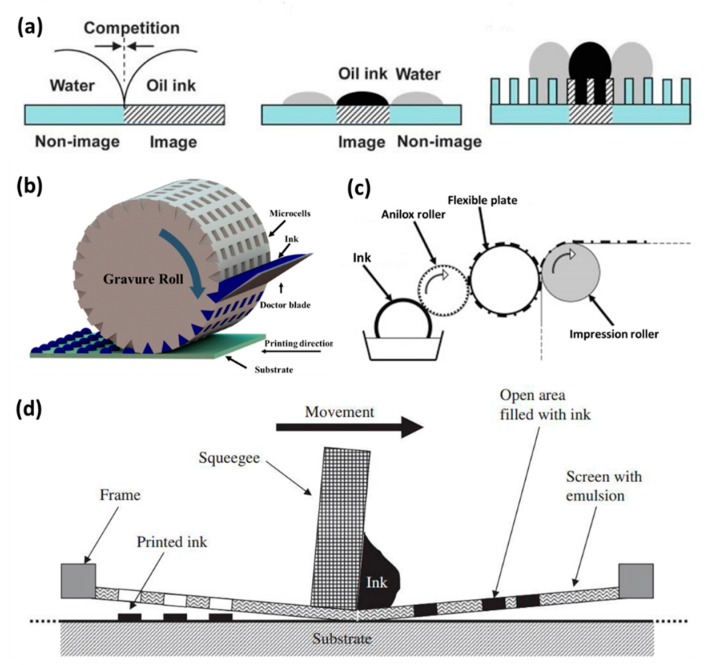

Figure 1.

(a) The scheme is the role of plate for controlling ink patterning in offset printing technique. The hydrophilic area is the non-image area, and the other area is the image area. The effect of surface energy and surface structure on the wetting behavior of oil ink and water are exhibited. The water is on the hydrophilic and non-image area which could repel the oil ink. The plate is the chemically patterned flat plate. The plate is the chemically and structured patterned plate. Reproduced from [33], with permission from Royal Society of Chemistry, 2013; (b) The processing steps of gravure printing: ink filling in the microcells, the doctor blade wiping the ink, ink transferring to the substrate, the functional material patterning formation. Reproduced from [35], with permission from American Chemical Society, 2014; (c) The processing steps of flexographic printing: ink transferring to the anilox roller, ink transferring to the flexible plate, ink transferring to the substrate with the impression roller; (d) The processing steps of screen printing. The ink is squeezed through the pores from the mesh plate with the auto device, and then the functional ink is deposited onto the required area of printing substrate. Reproduced from [40], with permission from Elsevier, 2009.