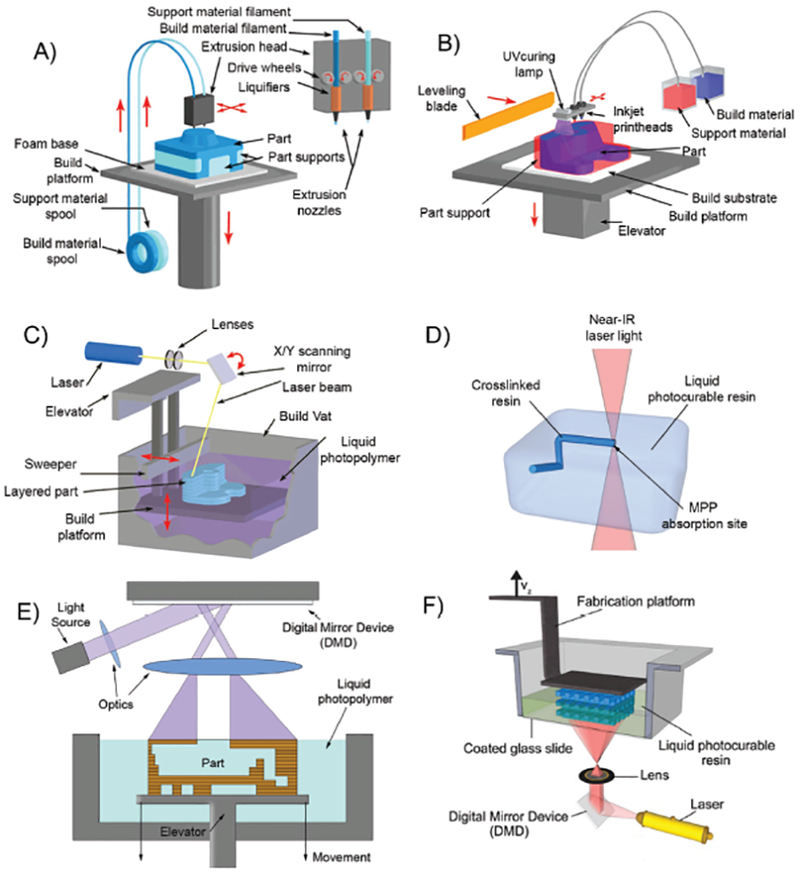

Figure 1.

Schematic overview of various E-3DP and L-3DP modalities. A) E-3DP: Schematic of an FDM 3D-printer, where thermoplastic filaments spool through a heated nozzle extruder. B) E-3DP: Schematic of an MJM 3D-printer, where materials are jetted via printheads. The variant pictured photopolymerizes the dispensed droplets in place. C) L-3DP: Schematic of a traditional SLA 3D-printer, where a laser beam is raster-scanned across the surface of a photopolymerizable resin as a build stage within moves. A–C) Adapted with permission.[5] Copyright 2016, The Royal Society of Chemistry. D) L-3DP: Multiphoton polymerization 3D-printing, where nonlinear photon absorption from a laser into a photopolymerizable resin creates structures as the laser is traced in 3D space. E) L-3DP: The “free surface” configuration digital-light-processing 3D-printing, where a 2D cross-section of light strikes the air–liquid surface of a photopolymerizable resin as a build stage sinks into the vat. F) L-3DP: The “bat” configuration of digital-light-processing 3D-printing, where a 2D cross-section of light strikes the bottom of a transparent vat of photopolymerizable resin, as a build stage pulls out of the vat. D,F) Adapted with permission.[6] Copyright 2012, Elsevier.