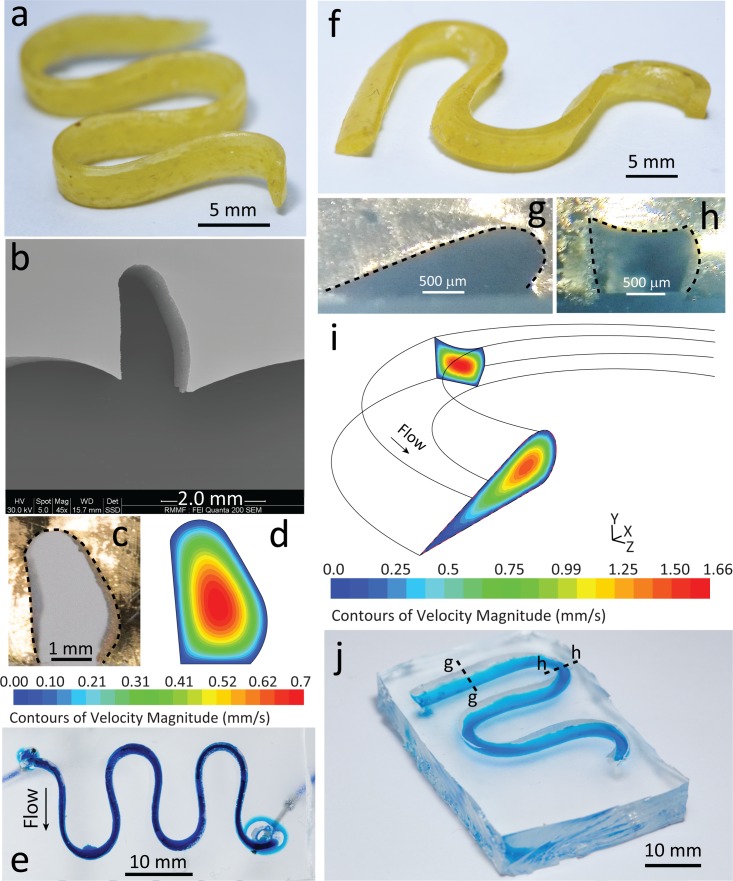

FIG. 6.

3D microfluidic structures with unconventional cross-sections fabricated from flat pasta via pasta templating. (a) Pasta arranged in a serpentine formation, to produce a channel with high aspect ratio. (b) SEM shows semi-oblong cross-section and bowing at the bottom of the channel. (c) Cross-section of channel after mechanical clamping. (d) Flow velocity contours based on the clamped cross-section obtained at 50 μl/min. (e) Bottom view of high aspect ratio channel filled with blue stained water for better visualisation. (f) Pasta arranged in a serpentine formation deformed at a 45° angle, to produce a twisted serpentine structure. Cross-sections both at the (g) curved and (h) straight sections of the structure after clamping. (i) Velocity contours at the prescribed cross-sections obtained at 50 μl/min. (j) Isometric view of twisted serpentine structure filled with blue stained water, to emphasise its 3D nature. Dashed lines indicate point of dissection for the previous cross-sections.