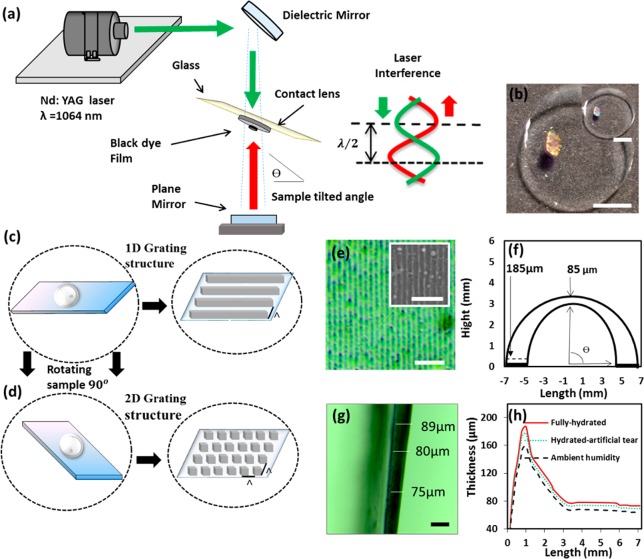

Figure 1.

Fabrication of 1D nanopatterns on a contact lens through DLIP in holographic Denisyuk reflection mode. (a) Nd:YAG laser beam (1064 nm, 3.5 ns) was guided by a mirror and passed through a dyed contact lens and reflected back from a plane mirror to ablate localized regions in the recording medium. (b) Fabricated ink-based holographic nanostructures on contact lenses (scale bar = 5 mm). Schematics of (c) 1D and (d) 2D nanostructures. (e) Optical microscopy image of a 1D nanostructure surface. The inset shows the SEM image of the surface topography (scale bar = 5 μm). (f) Contact lens geometry and thickness distribution. (g) Optical image of a contact lens cross section in ambient humidity conditions (scale bar = 100 μm). (h) Contact lens thickness variations in ambient humidity, fully hydrated condition (in DI water), and hydrated condition (in artificial tear).