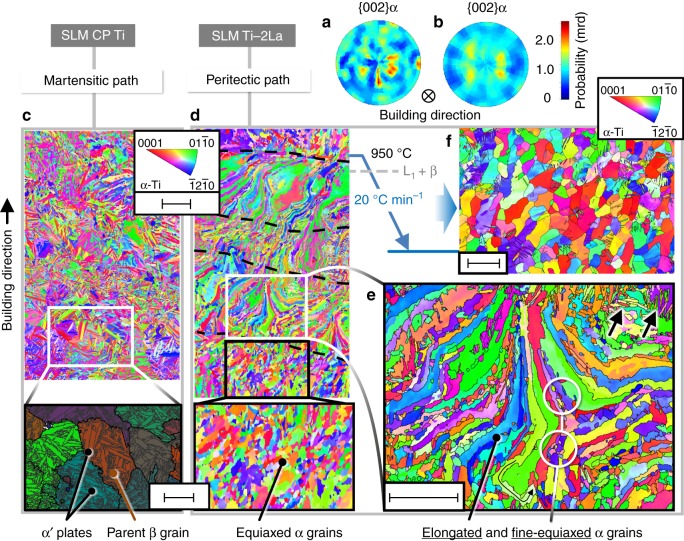

Fig. 2.

Texture modification during selective laser melting (SLM) of Ti-2wt.% La (Ti-2La). The addition of 2wt.% La to commercially pure titanium grade 1 (CP Ti) leads to an attenuation of the preferential orientation of α phase along the building direction as shown in a, b: normalized pole figures of {002}α reconstructed from a gauge volume of 1 × 1 × 5 mm3 for CP Ti and Ti-2La, respectively. c The martensitic microstructure of CP Ti consists of α′ plates extending within parent β grains according to the Burgers OR. Texture attenuation occurs as a consequence of arrangements of small equiaxed α grains with multiple orientations, nucleated in Ti-2La as shown in d and e (e.g., see encircled grains). f Post- thermal treatment of the SLM as-built condition via slow cooling with 20 °C min−1 from 950 °C passing through the peritectic line (i.e., from L1 + β field down to room temperature) provokes the formation of new α grains and extensive globularization, leading to a recrystallized-like microstructure. Black lines in e, f indicate high-angle grain boundaries (misorientation >10°). The scale bars in c, d and in its magnified regions (at the bottom) are 100 μm and 50 μm, respectively; in e and f, 50 μm