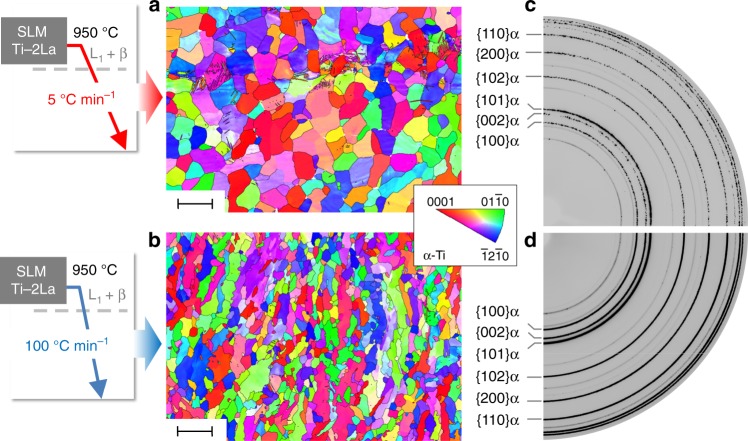

Fig. 3.

Grain refinement in the Ti-2wt.% La (Ti-2La) alloy after selective laser melting (SLM). Post thermal treatment of the SLM as-built condition by cooling with a 5 °C min−1 and b 100 °C min−1 from 950 °C (L1 + β field) down to room temperature, results in the formation of new α grains of smaller size with increasing cooling rate and extensive globularization. Scale bars, 50 μm. c, d Representative quarters of Debye–Scherrer rings obtained for a gauge volume of 1 × 1 × 5 mm3 and the microstructures shown in a, b respectively. The spotty rings obtained for 5 °C min−1 compared with the continuous {hkl}α rings shown for 100 °C min−1, reflects for the latter a remarkably smaller grain size in the bulk of the alloy. Black lines in a, b indicate high angle grain boundaries (misorientation >10°)