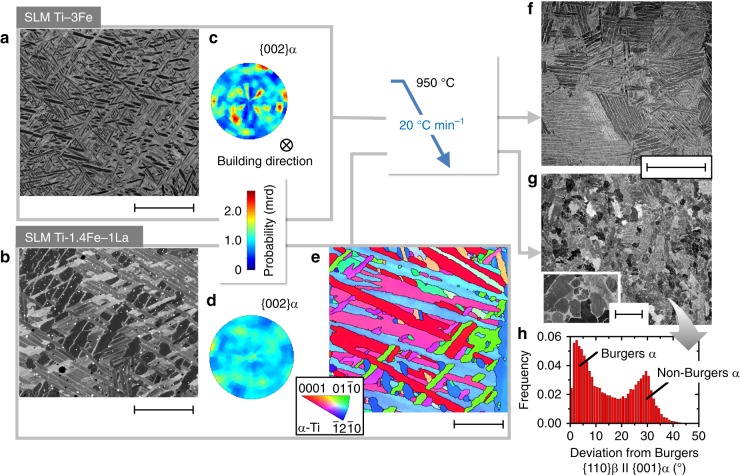

Fig. 5.

Reducing solidification texture during additive manufacturing of titanium alloys. Formation of fine α particles with multiple orientations occurs within colonies of α lamellae by addition of the peritectic forming solute La. a, b Transformation of α during selective laser melting (SLM) of Ti-3wt.% Fe (Ti-3Fe) and Ti-1.4Fe-1La (wt.%), respectively (scale bars, 10 μm). For the first case, α forms directly from parent β grains: the typical path of β → α transformation that results in a lamellar α+β microstructure. For the second, an additional path of α formation not linked with the orientation relationship of the parent β phase takes place. This is reflected in c, d: normalized pole figures of {002}α reconstructed from a gauge volume of 1 × 1 × 5 mm3 for Ti-3Fe and Ti-1.4Fe-1La, respectively. e α particles of diverse orientations that can reach diameters <1 μm form at boundaries of α lamellae during SLM of Ti-1.4Fe-1La. Black lines indicate high angle grain boundaries (misorientation >10°). Scale bar, 5 μm. f, g Post thermal treatment by slow cooling the Ti-3Fe and Ti-1.4Fe-1La alloys from 950 °C with 20 °C min−1 down to room temperature, leads on the one hand, to a typical lamellar α + β microstructure and on the other, to extensive globularization of α, respectively. Scale bars in f and g, 250 μm; 30 μm in the inset of g. h The two paths of α formation taking place for the heat treated Ti-1.4Fe-1La alloy are reflected in the bi-modal distribution obtained for lattice correlation boundaries between α and β phases