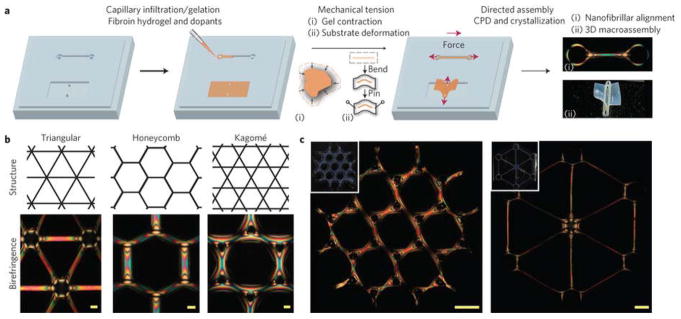

Figure 4. Mechanical tension-mediated formation of patterned nanofibrillar structure.

(a) General schematic of the directed assembly protocol. Aqueous silk fibroin is mixed with crosslinkers hydrogen peroxide and horseradish peroxidase and infiltrated/gelled in a PDMS mold. Mechanical tension is subsequently introduced by either contraction of the gel in mixtures of ethanol and water, or direct deformation of the elastomeric substrate. Finally, as the structures undergo critical point drying (CPD), β-sheet physical crosslinking in the silk is induced, stabilizing the material in its mechanically modified state. The final structure possesses tension-engineered nano-, micro- and macrostructure. b, Birefringence of sample microscale, nanofibrillar unit cells generated from periodic shapes. Scale bars, 100 μm. (c) Large-scale structures composed of tri-hexagonal and triangular components. Inset: camera images of the whole structure taken under diffuse white light. Scale bars, 1 mm. Adapted with permission from ref 29. Copyright 2017 Springer Nature.