Table 4.

Used nozzle diameters and cylinder ratios and obtained gel particles via the internal setting method.

|

Gel Particles Obtained from a 2 wt. % Amidated Pectin Solution by the Internal Setting Method

(Nozzle Diameter/Cylinder Ratio, Black Bar Corresponds to 200 μm) | |||

| 450/1.2 | 450/1.6 | 450/1.9 | 450/3.4 |

|

|

|

|

| 450/3.8 | 450/8.0 | 450/11.5 | 450/11.6 |

|

|

|

|

| 500/0.9 | 500/4.7 | 500/9.6 | |

|

|

|

|

|

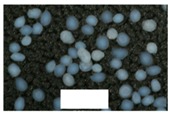

Gel particles obtained from a 3 wt. % sodium alginate solution by the internal setting method

(nozzle diameter/cylinder ratio, alginate concentration, white bar corresponds to 5 mm) | |||

| 300/8.7 | 500/6.0 | 500/9.4 | |

|

|

|

|