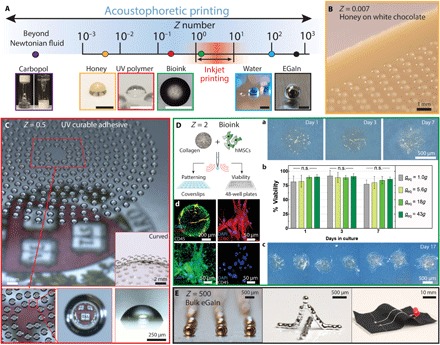

Fig. 4. Acoustophoretic printing of food, optical, biological, and electrically conductive materials.

(A) Schematic illustration of the broad Z range enabled by acoustophoretic printing, which extends over nearly six orders of magnitude, and corresponding images of droplets patterned by this approach. Note that the typical Z range for inkjet printing is highlighted in red. Scale bars, 500 μm. (B) Honey droplets printed on white chocolate. (C) Optical adhesive resin printed in a spiral motif yielding a microlens array. (D) Acoustophoretic printing of hMSC-laden collagen I ink for viability testing and patterning. (a) Bright-field images of printed droplets composed of hMSCs in a collagen I matrix (geq = 43g) cultured for 7 days. (b) Cell viability of acoustophoretically printed droplets with increasing acoustic force (n = 6). n.s., not significant. (c) Bright-field image of patterned droplets at day 17 (geq = 18g). (d) Representative confocal microscopy images of an immunofluorescently stained, printed droplet (geq = 43g) cultured to day 17 and a higher-magnification region stained for CD105 (green), CD90 (red), CD45 (gray), and nuclei [4′,6-diamidino-2-phenylindole (DAPI), blue]. (E) Acoustophoretic printing of a liquid metal ink composed of eGaIn patterned as individual droplets at room temperature in noncontact mode.