Table 1:

Screening of the reaction conditions.

| ||||

|---|---|---|---|---|

| Entry | 1 | Conditions | Conv. [%] | Yield [%] (Z/E) |

| 1 | 1a | 5% JohnPhosAuNTf2 | <5 | – |

| 2 | 1b | 5% JohnPhosAuNTf2 | 100 | messy |

| 3 | 1c | 5% JohnPhosAuNTf2 | 100 | 79 (3:2) |

| 4 | 1c | 5% PPh3AuNTf2 | 100 | 80 (3:2) |

| 5 | 1c | 5% RuPhosAuNTf2 | 100 | 80 (3:1) |

| 6 | 1c | 5% IPrAuNTf2 | 100 | 96 (Z only) |

| 7 | 1c | 5% IPrAuCl | <10 | <5 |

| 8 | 1c | other [Au] catalysts | <90% yield[a] | |

| 9 | 1c | 5% IPrAuNTf2 (other solvents) | 40–90% yield[a] | |

| 10 | 1c | other metal catalysts (Ag, Cu, Fe, Pd, Rh, Ir, Zn, La, etc.) | <5% conversion[a] | |

| 11 | 1c | 1% IPrAuNTf2 (c=0.5m, 608C) | 100 | 98 (Z only) |

| 12 | 1c | 0.1% IPrAuNTf2 (c=2.0m, 608C), 48 h, gram scale | 100 | 95 (Z only) |

| 13 | 1c | 1% IPrAuNTf2 (c=0.5 m, 408C, 48 h) | 93 | 88 (Z only) |

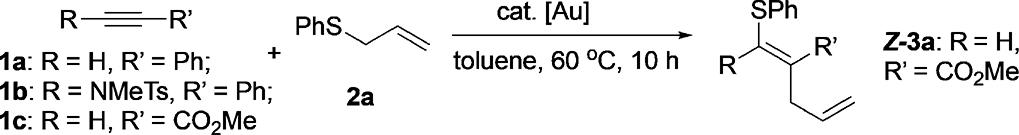

Reaction conditions: The catalyst (5 mol%) was added to a solution of alkyne 1 (0.15 mmol) and allyl sulfide 2a (0.1 mmol) in toluene (1 mL), and the reaction mixture was kept at 60°C for 10 h. Conversion and yield were determined by 1H NMR spectroscopy with dimethyl sulfone as the internal standard.

See the Supporting Information.