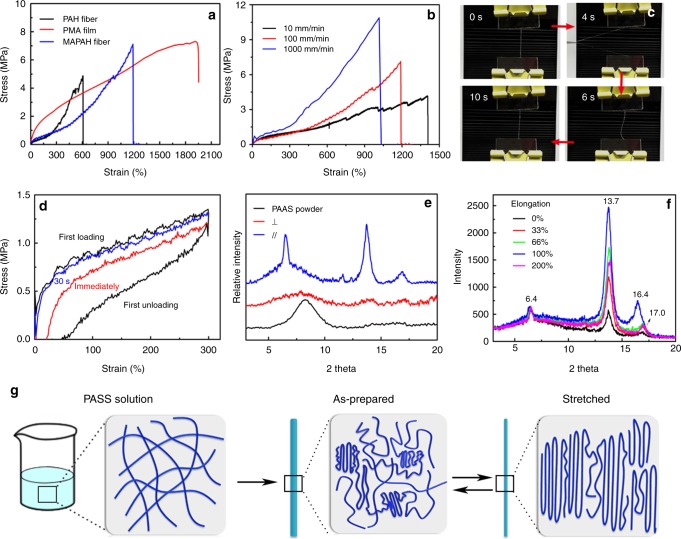

Fig. 3.

Mechanical and structural characterization of hydrogel fibers. a Stress–strain profiles of a PMA film, PAH, and MAPAH fibers at 100 mm min−1 stretching rate. b Stress–strain profiles of a MAPAH fiber under different stretching rates. c Photograph of a MAPAH fiber showing the hysteresis effect during its recovery process. d Stress–strain profiles of a MAPAH fiber subjected to a loading–unloading cycle at 300% strain (black curve). Immediately after the 1st cycle, the fiber was stretched to 300% strain (red curve). The same fiber was unloaded and stretched to 300% strain after a 30 s recovery at ambient condition (blue curve). e XRD spectra of PAAS powder, and MAPAH fibers placed parallel or perpendicular to the X-ray incidence direction. f XRD spectra of MAPAH fibers under different stretching strains. g Proposed molecular organization and orientation of PAAS chains at different conditions. PAAS is solvated and randomly oriented in solution. Coexistence of crystalline and amorphous domains in as-prepared hydrogel fibers. Mechanical stress enables PAAS chains a higher degree of crystallization and orientation along the strain direction