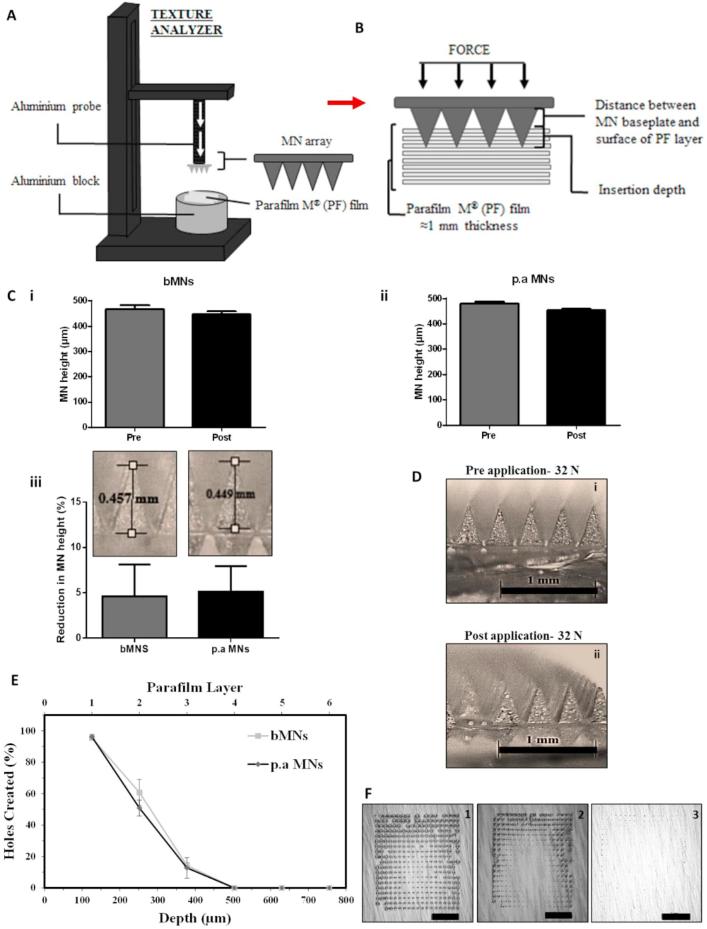

Fig. 3.

Mechanical characterisation of MN arrays. Diagrammatic representation of the MN compression (A) and insertion into Parafilm M® (B) test method. (C) MN height pre- and post-compression (32 N) at 1.19 m/s, held for 30 s (mean ± SD, n = 5), bMNs (i) and p.a MNs (ii). Comparison of percentage reduction in MN height of MN arrays prepared from different formulations (iii). (D) Representative images of p.a MNs pre- (i) and (ii) post-application of 32 N (the scale bars represent 1 mm). (E) Percentage of holes created in each Parafilm M® layer and their corresponding insertion depth, using a force of 32 N for bMNs and p.a MNs, mean ± SD, n = 5. (F) Representative microscope images of Parafilm M® layers after insertion of p.a MNs showing first (1), second (2), and third (3) Parafilm M® layers (the scale bar represents 2 mm).