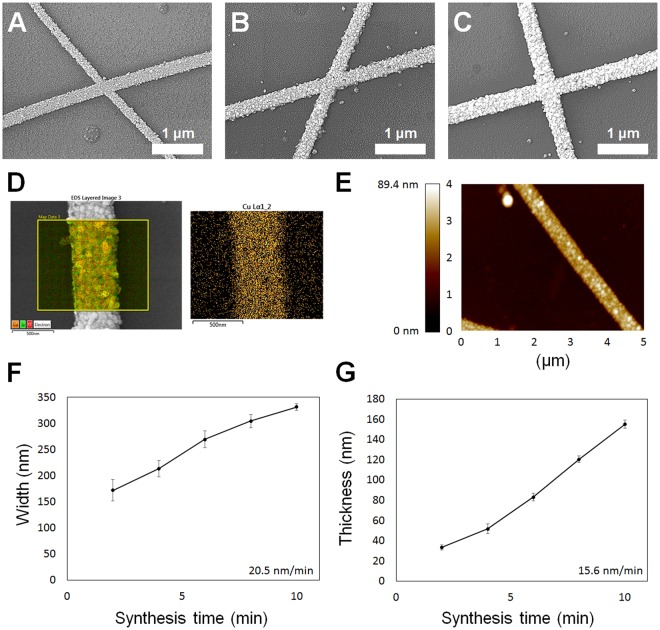

Figure 2.

Analysis of copper nanowire fabrication conditions and morphology. (A–C) Scanning electron microscopy (SEM) images of copper nanowires deposited for 2, 6, and 10 min, respectively. (D) Fabricated copper nanowire and its component analysis maps determined by energy dispersive X-ray spectroscopy (EDS). (E) Atomic force microscopy (AFM) analysis map showing nanowire thickness and morphology. (F) Graph showing correlation between electroless deposition time and nanowire width (n = 5, mean ± standard error). (G) Graph showing correlation between electroless deposition time and nanowire thickness (n = 5, mean ± standard error).