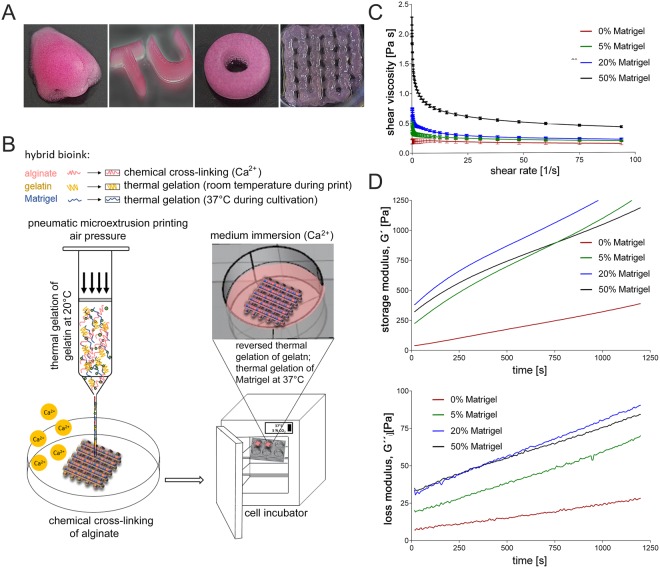

Figure 1.

Experimental design with images of 3D printed constructs and rheological characterization of hybrid alginate/gelatin/Matrigel bioinks. (A) Image of constructs of different shapes and complexity generated by extrusion printing with the bioink optimized in the present study, consisting of 2% alginate, 3% gelatin, and 20% Matrigel. (B) Schematic workflow of the 3D printing procedure. Bioink components and living A549 cells were mixed thoroughly with two syringes connected by a Luer-Lock-adapter. Following initial Ca2+-driven cross-linking, the hydrogel was transferred into the dispensing cartridge in the print head and pneumatically extruded onto a dry petri dish. Thermal gelation of gelatin maintained the 3D structure of the construct during the printing process. Alginate was completely cross-linked by submersion in a CaCl2 solution. During incubation at 37 °C the gelatin dissolves, while the Matrigel gelation takes over support of the structural stability. (C) Viscosity of the uncross-linked hybrid bioinks was recorded dependent on a shear rate sweep of 1–100 s−1 at 24 °C. (D) Storage and loss modulus (G′ and G″) of the bioink formulations were measured at frequencies of 1 Hz and 1% shear strain after adding CaSO4 to determine viscoelastic properties of the cross-linked bioinks at 24 °C.