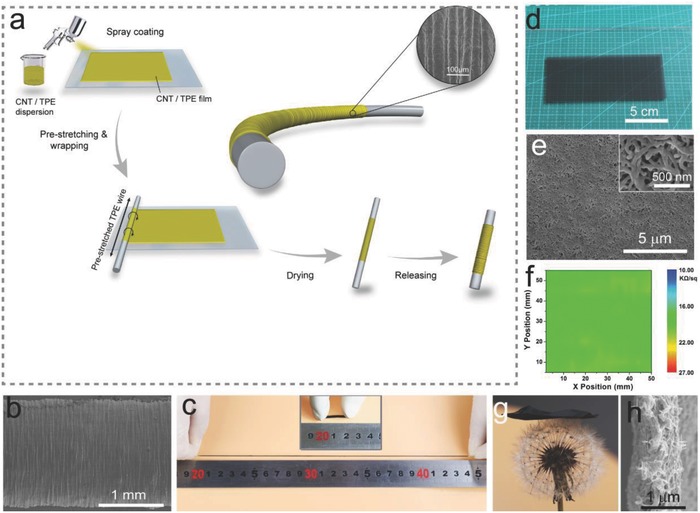

Figure 1.

Preparation and characterization of the ultrastretchable fiber strain sensor. a) Schematic illustration of the fabrication procedure for the strain sensor. b) SEM image of the NTTFn@fiber strain sensor with five layers of NTTFs. The fabrication of the strain sensor was 1600%. c) Optical images showing a fiber strain sensor at a 1100% strained state and relaxed state (Inset), respectively. d) Photograph of the MWCNT/TPE composite film (NTTF) with a filler load of 12 wt% on silica glass. The size of the film was 15 × 8 cm2. e) SEM image of a 12 wt% MWCNT/TPE composite film treated with ethanol for 2 min. The inset shows a high‐resolution SEM image. f) Sheet resistance distribution of a 12 wt% MWCNT/TPE composite film measured over an area of 50 × 50 mm2. g) Photograph of a MWCNT/TPE composite film (2.5 × 2.5 cm2) on a dandelion. h) SEM image showing the cross‐sectional micromorphology of a MWCNT/TPE composite film treated with ethanol for 2 min. The thickness of the film was 800 nm.