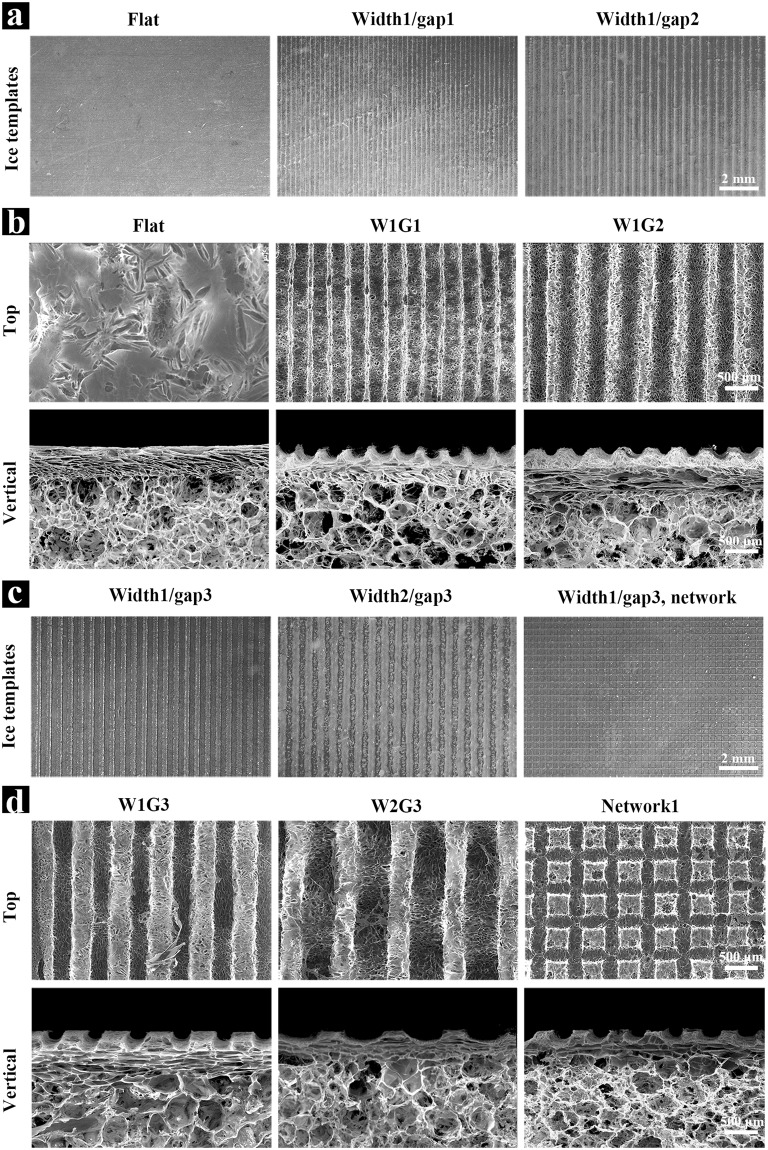

Figure 1.

Preparation of microgrooved DEX-BCP-Col composite scaffolds. (a and c) Images of ice line templates with different dimensions and intervals prepared from water dispensing. (b and d) SEM images of microgrooved DEX-BCP-Col composite scaffolds. Flat: control DEX-BCP-Col composite scaffold without microgrooves. W1G1, W1G2 and W1G3: DEX-BCP-Col composite scaffolds bearing parallel microgrooves with a same concave width of 290 ± 21 µm and a different convex ridge width of 47 ± 8, 153 ± 15 and 352 ± 23 µm. W2G3: DEX-BCP-Col composite scaffolds bearing parallel microgrooves with a concave width of 493 ± 30 µm and a convex ridge width of 357 ± 14 µm. Network: DEX-BCP-Col composite scaffold bearing grid network of microgrooves with a concave width of 297 ± 17 µm and a convex ridge width of 346 ± 11 µm. For (b) and (d), upper images show the top view and lower images show the vertical cross-sectional view of different scaffolds.